Top 10 Industrial Robotics Innovations Revolutionizing Manufacturing

The landscape of manufacturing is undergoing a seismic shift, driven by innovative advancements in industrial robotics. Experts predict that these technologies will redefine productivity and efficiency in factories. Dr. Alice Thompson, a leading voice in industrial robotics, once stated, "Innovation in robotics will unlock new levels of production we’ve only dreamed of." Her insight captures the essence of the ongoing transformation.

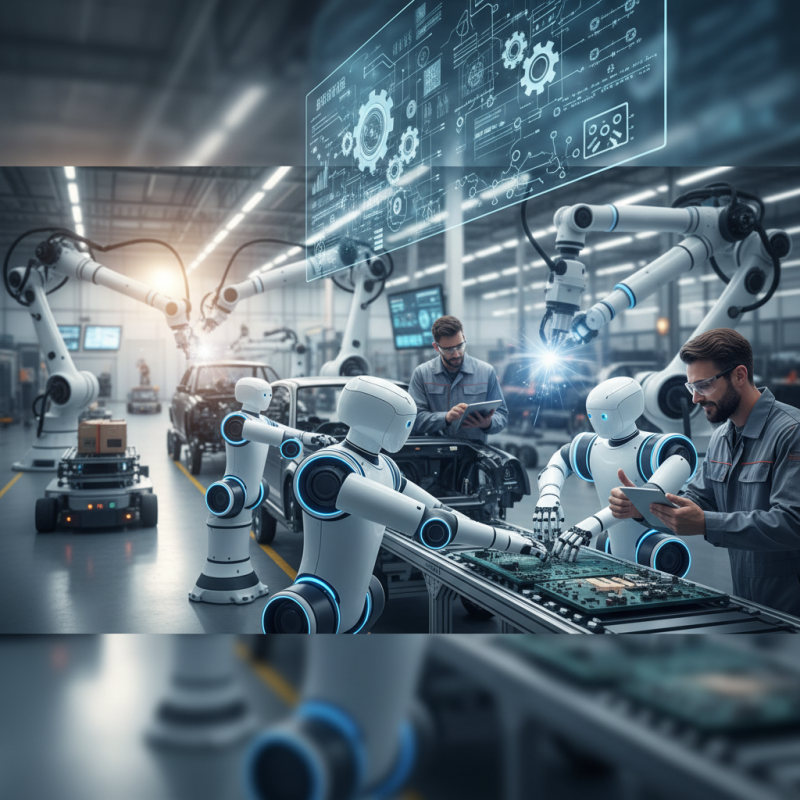

Today’s industrial robotics innovations are rapidly changing how businesses operate. Robots are no longer just tools; they are intelligent systems enhancing human capabilities. For instance, collaborative robots work side by side with employees, making processes safer and more efficient.

However, this rapid evolution also poses challenges. Companies must rethink workforce dynamics and address potential job displacement. It's not just about adopting new technology but also about integrating it wisely. Industrial robotics has the power to improve output while requiring careful consideration of its broader impact on society.

Key Trends in Industrial Robotics Transforming Manufacturing Processes

The manufacturing landscape is rapidly evolving. Key trends in industrial robotics are predominantly shaping these changes. Collaborative robots, or cobots, are making their presence known. They work alongside human operators, enhancing productivity without replacing jobs. This synergy fosters a safer workspace and increases overall efficiency.

Manufacturers are utilizing AI-driven robots for predictive maintenance. These robots analyze data in real-time to identify potential issues before they become problems. Such proactive measures reduce downtime significantly. However, relying solely on these systems can create blind spots. Regular human oversight remains crucial to ensure robustness and reliability.

Tip: Embrace flexibility in your automation strategies. Don’t just focus on the latest tech. Evaluate your specific needs and capabilities.

Another intriguing trend is the use of 3D printing and robotics integration. This marriage allows for rapid prototyping and customizable products. While the technology offers great promise, it’s still in its infancy. The quality control processes need refinement to ensure consistent results.

Tip: Always prioritize training for your workforce. New technologies can create challenges. Understanding these tools is vital for maximizing their potential.

Breakthrough Technologies Enhancing Robot Flexibility and Precision

The landscape of manufacturing is changing rapidly. Breakthrough technologies are enhancing the flexibility and precision of industrial robots. These innovations help robots perform tasks that were once impossible. Modern robots can easily adapt to different assembly lines. This capability leads to increased productivity and efficiency.

One example of this innovation is advanced machine learning algorithms. These algorithms allow robots to learn from their environments. They can adjust their movements in real-time. This flexibility reduces the need for manual recalibration. However, this reliance on algorithms presents challenges. Robots sometimes misinterpret data. Minor errors can lead to significant production setbacks.

Another impactful development is the integration of artificial intelligence. AI helps robots understand complex tasks better. This improvement enhances accuracy during manufacturing processes. Yet, there's a fine line between automation and human oversight. Over-reliance on technology can lead to skill gaps in the workforce. Manufacturers must balance innovation with the need for training and support.

Integrating AI and Machine Learning for Smarter Industrial Robotics

The landscape of industrial robotics is rapidly evolving. AI and machine learning are key drivers behind this transformation. Recent reports estimate that AI will increase manufacturing productivity by up to 40% in the next decade. This is significant for companies looking to enhance efficiency and reduce costs.

Integrating AI allows robots to adapt to various tasks. They can learn from their environment, improving their performance over time. For instance, 85% of manufacturers recognize the need for smarter robots in their operations. By utilizing data analytics, companies can optimize workflows and predict maintenance needs. However, some industries are still hesitant. They fear job losses and the costs of implementation. This paradox needs addressing as the technology powers forward.

Tips: Start small. Implement AI in one process and analyze results. Gradually expand to other areas. This reduces risks and builds confidence in robotic solutions. Explore partnerships with tech firms for better insights. Consider training current employees to work alongside new technologies. Investing in people is just as important. Balancing innovation with workforce stability is crucial for long-term success.

Advancements in Collaborative Robots: Safety and Efficiency in Workspaces

Collaborative robots, or cobots, are reshaping modern manufacturing. They work alongside humans, enhancing safety and efficiency. These robots perform repetitive tasks, allowing workers to focus on more complex activities. Workers feel more comfortable, knowing that cobots are designed to avoid accidents and injuries. This collaborative approach can reduce workplace stress.

Despite their advantages, cobots come with challenges. Proper training is essential for employees. Many still fear job displacement due to automation. Communication between humans and robots can be difficult. For cobots to be effective, systems must be intuitive. Designers need to consider human factors more. Sometimes, the integration of cobots slows down workflows instead of improving them.

The evolution of cobots introduces new possibilities. They are equipped with advanced sensors and AI technology. This allows them to adapt to changing environments. However, reliance on technology raises concerns. Can we trust these robots entirely? As we integrate cobots deeper into manufacturing, careful evaluation is crucial. The goal is to create harmonious workspaces where both humans and robots thrive.

Top 10 Industrial Robotics Innovations Revolutionizing Manufacturing

| Innovation | Key Features | Impact on Manufacturing | Safety Enhancements |

|---|---|---|---|

| Collaborative Robots (Cobots) | User-friendly programming, flexible deployment | Increased production efficiency and adaptability | Sensor technology for human proximity detection |

| AI-Powered Robotics | Machine learning algorithms for improved task management | Higher precision and reduced errors in assembly | Advanced decision-making in dynamic environments |

| Mobile Robotics | Autonomous navigation and transport capability | Streamlined material handling processes | Obstacle detection for safer operation |

| Robotics-as-a-Service (RaaS) | Subscription-based access to robotic technology | Lower capital expenditure for small businesses | Continuous software updates for safety compliance |

| Smart Sensors in Robotics | Real-time data acquisition and analysis | Enhanced monitoring and predictive maintenance | Increased operational safety through real-time feedback |

| Wearable Robotics | Exoskeletons for human augmentation of strength | Reduced physical strain on workers | Enhanced ergonomics and safety in physical tasks |

| 3D Printing Integration with Robotics | On-demand production capabilities | Shorter lead times and reduced waste | Safer processes with fewer manual interventions |

| Remote Monitoring and Control | Cloud-based access and control systems | Operational efficiency from remote locations | Improved safety through distance operation |

| Advanced Gripping Technologies | Adaptive grips for various shapes and materials | Versatility in handling diverse products | Minimized risk of dropped items during handling |

The Role of Automation in Reducing Production Costs and Enhancing Output

In the world of manufacturing, automation is a game changer. It significantly reduces production costs while enhancing output quality. Integrating robotics into production lines allows companies to operate more efficiently. Tasks that were once labor-intensive are now handled by robots, streamlining processes.

Tips: Invest in staff training. A skilled workforce can better manage and maintain these robotic systems.

Automation also offers consistency. Robots perform repetitive tasks with precision. This reduces errors and waste. However, the initial investment in robotics can be daunting for some companies. It's essential to have a clear strategy to maximize returns on this investment.

Tips: Start small. Implement robotics in one area before expanding. This provides insights into effectiveness and challenges.

Some companies may hesitate due to a fear of job loss. However, automation can create new job opportunities in tech and maintenance sectors. Embracing change is vital. Regular assessments of automated systems are necessary to ensure they function optimally. Adjustments may be needed as production needs evolve.

Top 10 Industrial Robotics Innovations Impacting Manufacturing

Related Posts

-

Revolutionizing Manufacturing: How Industrial Robotics Are Shaping the Future of Automation

-

The Rapid Growth of Industrial Robotics Revolutionizing Manufacturing with 80 Percent Productivity Increase

-

How to Choose the Right Manufacturing Robots for Your Production Needs

-

Why Choose a Pick and Place Robot? Boost Efficiency with 70% Increased Productivity

-

Top 7 Manufacturing Robots Revolutionizing the Industry in 2023

-

Exploring the Future of Manufacturing Robots in Smart Factories