Top ASRS Systems to Watch in 2025 for Warehouse Automation Solutions

As industries continue to evolve in the face of technological advancements, the need for efficient warehouse operations has never been more pressing. Automated Storage and Retrieval Systems (ASRS systems) have emerged as a pivotal solution to address the complexities of inventory management and logistics. By automating the storage and retrieval processes, ASRS systems not only enhance operational efficiency but also minimize human error, ultimately leading to reduced costs and improved productivity.

Looking ahead to 2025, various innovative ASRS systems are set to transform the landscape of warehouse automation solutions. These systems will leverage advancements in artificial intelligence, robotics, and data analytics to optimize workflows and increase throughput. As warehouses aspire to meet the growing demands of e-commerce and rapid delivery models, the integration of state-of-the-art ASRS systems will provide a competitive edge for businesses seeking to streamline their operations.

In this exploration of the top ASRS systems to watch in 2025, we will delve into key features, benefits, and emerging trends shaping the future of warehouse automation. Understanding these systems will be crucial for organizations aiming to enhance their logistics capabilities and remain agile in a fast-paced market.

Emerging Trends in ASRS Systems for 2025: A Comprehensive Overview

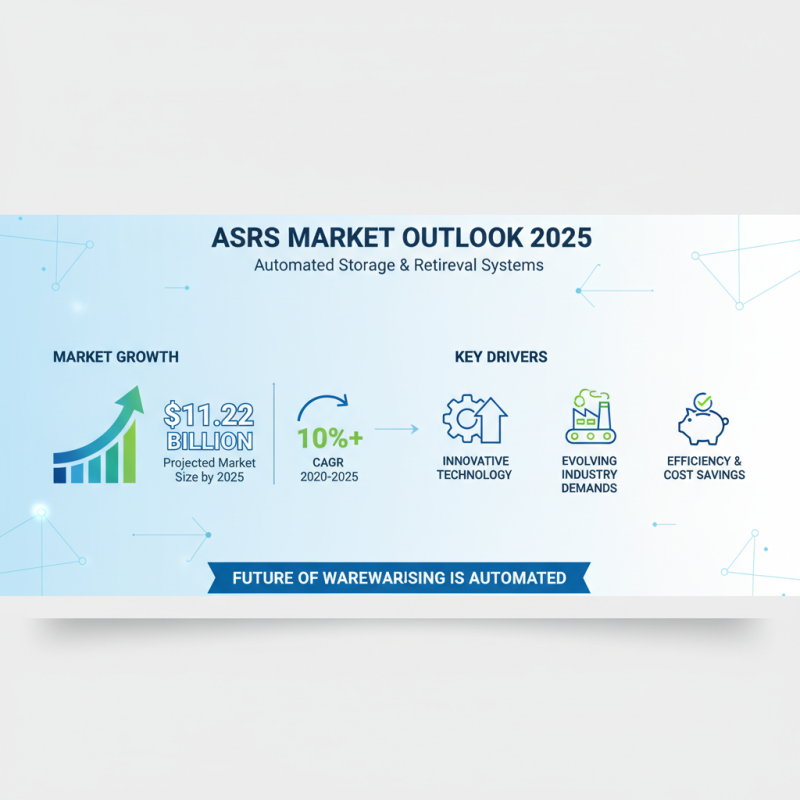

As we look ahead to 2025, the landscape of Automated Storage and Retrieval Systems (ASRS) is poised for significant transformation, driven by innovative technology and evolving industry demands. The global ASRS market size is projected to reach $11.22 billion by 2025, growing at a CAGR of over 10% from 2020 to 2025, according to a recent market research report. This growth signifies a shift towards greater automation in warehousing as companies increasingly recognize the efficiency and cost-saving benefits that ASRS can provide.

Emerging trends in ASRS systems include enhanced integration of AI and Machine Learning, which allow for improved inventory management and predictive analytics. These advancements enable smarter storage solutions that adapt in real-time, anticipating demand fluctuations and optimizing space utilization. Furthermore, the rise of e-commerce is driving demand for ASRS that can handle diverse product ranges with variability in order size and frequency. Recent studies indicate that warehouses utilizing ASRS systems achieve up to 60% higher throughput compared to traditional storage methods, underscoring the system's pivotal role in streamlining operations and reducing lead times in an increasingly competitive marketplace.

Additionally, sustainability is becoming a focal point for ASRS development, with manufacturers increasingly prioritizing energy efficiency and eco-friendly designs. Reports indicate that energy-efficient systems can reduce energy consumption by as much as 30%, reflecting an industry-wide commitment to reducing carbon footprints while improving operational performance. As we approach 2025, these advancements in ASRS technology herald a new era of efficiency and reliability in warehouse automation, aligning with the growing need for agile and sustainable supply chain solutions.

Key Technologies Driving Warehouse Automation in ASRS Solutions

As we look ahead to 2025, the landscape of Automated Storage and Retrieval Systems (ASRS) is set to undergo significant transformation driven by advancements in key technologies. Central to this evolution is the integration of artificial intelligence and machine learning. These technologies facilitate real-time data analysis, enabling ASRS to optimize inventory management and enhance operational efficiency. By leveraging predictive analytics, warehouses can anticipate demand fluctuations, ensuring they maintain the right stock levels without over-committing resources.

Robotics and automation also play critical roles in modern ASRS solutions. The incorporation of sophisticated robotic arms and autonomous mobile robots (AMRs) allows for seamless handling and storage of goods. As these systems become more agile, they not only reduce labor costs but also improve accuracy in order fulfillment. Moreover, innovations in sensor technology, such as RFID and IoT, provide enhanced visibility into inventory across the warehouse, allowing for a more streamlined operation.

Tips: To maximize the benefits of ASRS implementation, companies should prioritize regular training for employees on new technologies. This ensures that team members are well-equipped to maximize system capabilities, ultimately leading to enhanced productivity. Additionally, conducting periodic maintenance checks can prevent costly downtimes, ensuring operations run smoothly. Embracing these advancements now will position warehouses for a more automated and efficient future.

Market Growth Projections for ASRS Systems in the Next Five Years

The market for Automated Storage and Retrieval Systems (ASRS) is poised for significant growth over the next five years, driven by the increasing demand for warehouse automation solutions across various industries. As businesses seek to optimize their supply chain operations, the adoption of ASRS technology presents a viable way to enhance efficiency, reduce labor costs, and improve inventory management. Projections indicate that advancements in robotics and artificial intelligence will further accelerate the integration of ASRS systems, making them an essential component of modern warehousing strategies.

As e-commerce continues to expand and consumer expectations for faster delivery times rise, the need for scalable and efficient storage solutions becomes more critical. The global focus on sustainability will also play a role in shaping ASRS development, with manufacturers innovating to create systems that reduce energy consumption and waste. The combination of technological advancements and market pressures fosters an environment where ASRS systems are not only becoming more prevalent but are also evolving to meet the complexities of modern logistics. The outlook for ASRS systems in the coming years suggests a dynamic shift towards smarter and more adaptable solutions for warehouse automation.

Case Studies: Successful Implementations of ASRS in Warehousing

Automated Storage and Retrieval Systems (ASRS) have emerged as critical components in warehouse automation, enhancing efficiency and accuracy in inventory management. A recent industry report indicated that the global ASRS market is projected to grow at a CAGR of 10.7% from 2022 to 2027, driven largely by the increased demand for optimized storage solutions. One notable case study involved a major retail distribution center that implemented an ASRS solution, resulting in a 30% reduction in labor costs and a 25% decrease in order fulfillment time. Such implementations illustrate the profound impact ASRS can have on operational performance.

Another compelling example can be found in the automotive sector, where manufacturers have started utilizing ASRS to streamline their parts handling. A specific facility reported achieving a 40% increase in warehouse space utilization after integrating an ASRS. The precise retrieval capabilities not only accelerated their production timelines but also improved inventory accuracy to over 99%. These cases underscore the tangible benefits organizations are realizing through the adoption of ASRS technology, highlighting its crucial role in modern warehousing strategies as we advance towards 2025.

Top ASRS Systems to Watch in 2025 for Warehouse Automation Solutions - Case Studies: Successful Implementations of ASRS in Warehousing

| Case Study | Industry | ASRS Type | Implementation Year | Efficiency Gain (%) | ROI Period (Months) |

|---|---|---|---|---|---|

| Case Study A | E-commerce | Mini Load ASRS | 2023 | 35 | 18 |

| Case Study B | Pharmaceutical | Shuttle System | 2022 | 50 | 24 |

| Case Study C | Grocery | Unit Load ASRS | 2024 | 40 | 12 |

| Case Study D | Fashion Retail | Robotic ASRS | 2023 | 30 | 30 |

| Case Study E | Electronics | Vertical Lift Module | 2025 | 45 | 20 |

Challenges and Solutions in Adopting ASRS Technologies by 2025

As the demand for efficient warehouse solutions continues to rise, Automated Storage and Retrieval Systems (ASRS) are at the forefront of technology advancements in logistics. However, several challenges can hinder their adoption by 2025. A report from the Warehousing Management Association indicates that nearly 43% of industries cite high initial costs and complex integration processes as significant barriers. These upfront investments, coupled with the challenges of retrofitting existing warehouses to accommodate ASRS, have led many businesses to hesitate in making the switch.

To navigate these hurdles, companies are beginning to explore modular ASRS solutions that offer scalability and flexibility without the need for extensive overhauls of current systems. A study by Research and Markets predicts that the ASRS market will grow at a CAGR of 10.5% over the next five years, suggesting a shift towards smaller, more adaptable systems that can easily integrate with other technologies such as AI and IoT. Moreover, emphasizing training and change management will be essential, as the successful implementation of ASRS relies heavily on the workforce's ability to adapt to new technologies. By addressing these challenges head-on, organizations can unlock significant efficiencies and remain competitive in a rapidly evolving market landscape.

Related Posts

-

Understanding ASRS System Warehouse: Transform Your Storage Efficiency Today!

-

Why Is Automated Storage Essential for Modern Businesses?

-

What is ASRS Systems and How Do They Revolutionize Warehouse Operations

-

The Rapid Growth of Industrial Robotics Revolutionizing Manufacturing with 80 Percent Productivity Increase

-

Top 7 Manufacturing Robots Revolutionizing the Industry in 2023

-

2025 How to Choose the Best Machine Tending Robot for Your Business Needs