Revolutionizing Manufacturing: How Industrial Robotics Are Shaping the Future of Automation

The manufacturing landscape is undergoing a significant transformation, driven by the rapid advancement of industrial robotics. According to a recent report by the International Federation of Robotics, global sales of industrial robots reached over 400,000 units in 2021, reflecting a remarkable 27% increase compared to the previous year. This surge highlights the growing reliance on automation to enhance production efficiency, reduce labor costs, and ensure higher precision in manufacturing processes.

As businesses strive to adapt to the demands of Industry 4.0, the integration of smart technologies and robotic systems is becoming imperative. With projections estimating that the industrial robotics market will exceed $90 billion by 2026, it is clear that these technologies are not just shaping the future of manufacturing—they are revolutionizing it.

This article explores how industrial robotics are at the forefront of this transformation, driving innovations and redefining operational standards in various sectors.

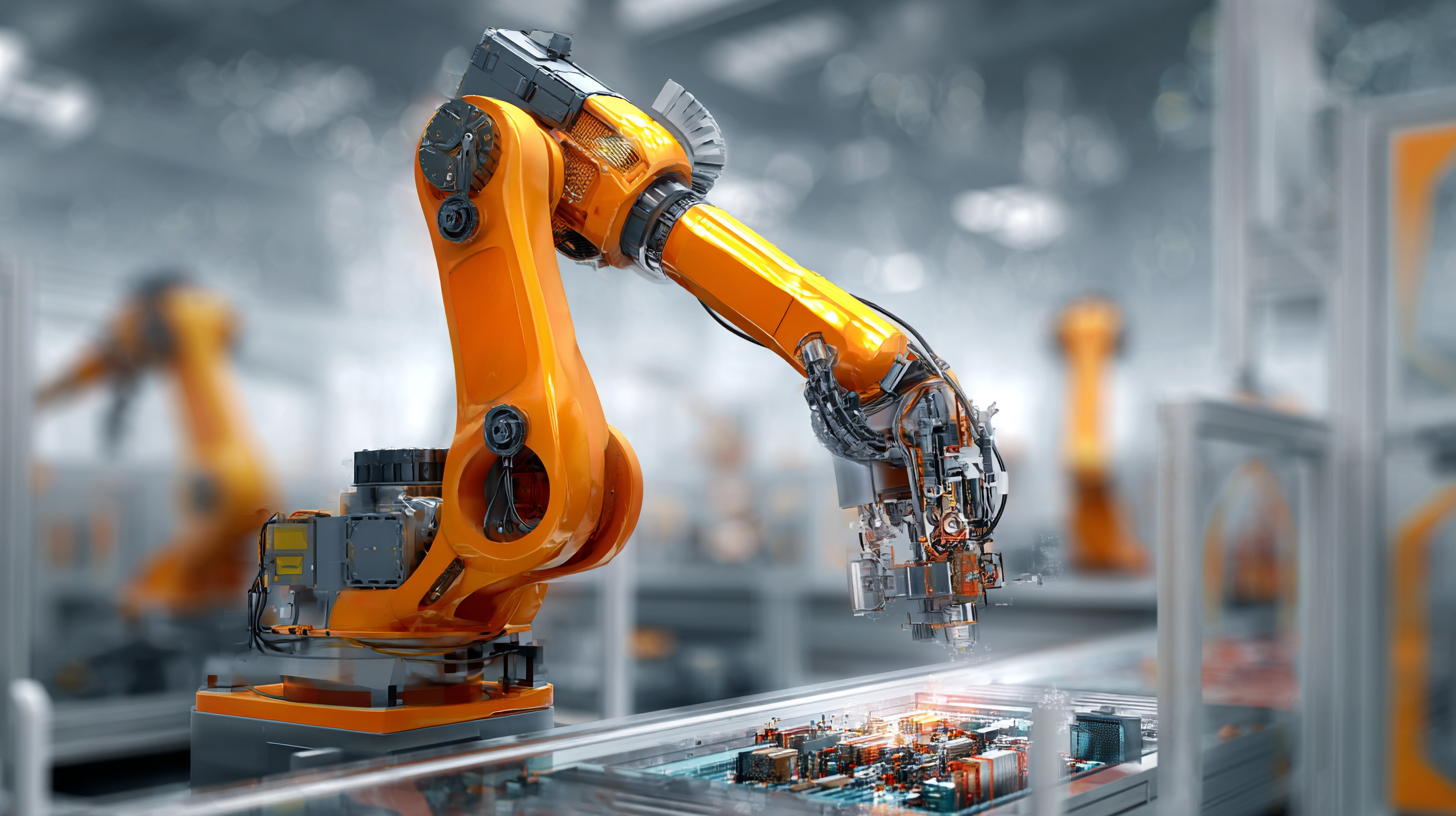

The Role of Industrial Robotics in Enhancing Production Efficiency

Industrial robotics are playing a transformative role in enhancing production efficiency across various sectors. By integrating advanced robotic systems into manufacturing processes, companies can drastically reduce operational costs, minimize human error, and significantly increase output. These robots can perform repetitive tasks with precision and speed, allowing human workers to focus on more complex and creative responsibilities. As a result, businesses can achieve higher productivity levels while maintaining superior quality in their products.

Industrial robotics are playing a transformative role in enhancing production efficiency across various sectors. By integrating advanced robotic systems into manufacturing processes, companies can drastically reduce operational costs, minimize human error, and significantly increase output. These robots can perform repetitive tasks with precision and speed, allowing human workers to focus on more complex and creative responsibilities. As a result, businesses can achieve higher productivity levels while maintaining superior quality in their products.

Tips: Ensure Successful Integration of Industrial Robotics

- When implementing robotics, start with a thorough analysis of your production line to identify areas that will benefit the most from automation.

- Invest in training programs for your staff to properly interact with and manage robotic systems, fostering a collaborative environment where human and machine work side by side.

- Regularly evaluate the performance of your robotic solutions and be open to making adjustments for continuous improvement.

Moreover, the flexibility and adaptability of industrial robots allow them to evolve with changing demands in the market. They can easily be reprogrammed or outfitted with different tools to meet various manufacturing needs. This versatility is particularly beneficial in industries facing rapid product lifecycle changes, ensuring that businesses remain competitive and responsive to consumer trends.

Transforming Workforce Dynamics: Robots and Human Collaboration in Factories

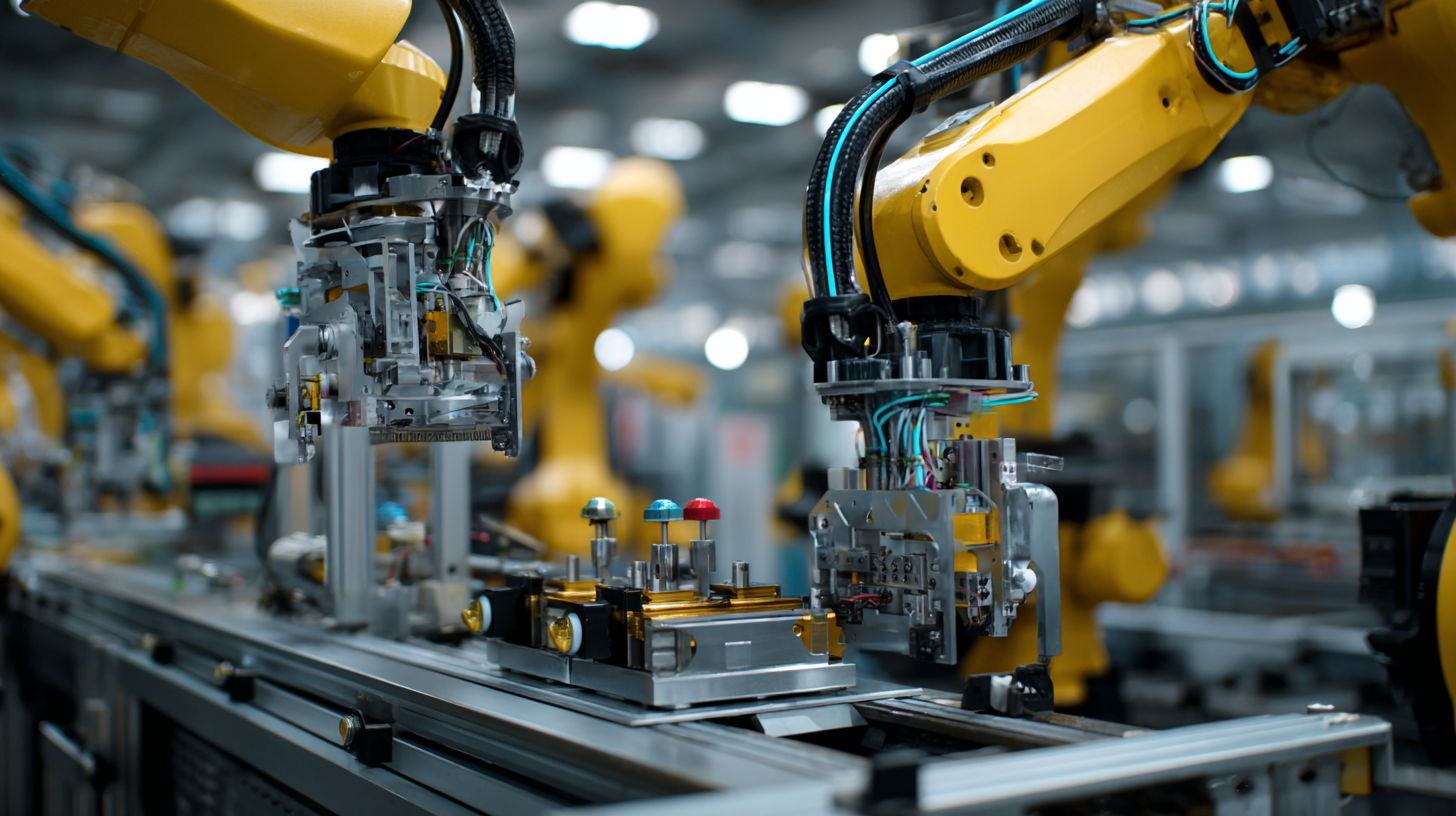

The integration of collaborative robots, or cobots, is transforming workforce dynamics in manufacturing facilities by facilitating a more synergistic relationship between robots and human workers. Unlike traditional automation that often replaces human labor, cobots are designed to complement and enhance human capabilities. This collaboration is critical in environments where agility and flexibility are paramount, allowing humans to focus on tasks that require creativity and problem-solving while leaving repetitive or hazardous tasks to robots.

Recent advancements in AI and robotics are further bolstering this partnership. Companies are leveraging AI-powered humanoid robots to streamline processes, significantly enhancing productivity in sectors such as automotive manufacturing. This shift not only improves operational efficiency but also creates new roles and opportunities for the workforce, underscoring the importance of upskilling to adapt to this evolving landscape. As the industry moves towards a more advanced phase, the emphasis on collaborative automation represents a pivotal change that prioritizes human-robot interaction, driving innovation and sustainability in manufacturing environments.

Exploring Cost Reduction: How Robotics Minimize Manufacturing Expenses

In the realm of manufacturing, the integration of industrial robotics has proven to be a game-changer, particularly in terms of cost reduction. According to a recent report by the International Federation of Robotics (IFR), companies that implement robotic systems can reduce operational costs by up to 30%. By automating repetitive tasks, businesses not only minimize labor costs but also enhance productivity, leading to substantial savings over time. These savings are particularly evident in industries such as automotive manufacturing, where precision and efficiency are paramount.

**Tip:** To maximize the benefits of robotics in cost reduction, manufacturers should conduct a thorough analysis of their production processes. Identifying bottlenecks where automation can be implemented most effectively can streamline operations and lead to significant expense reductions.

Furthermore, a study by McKinsey highlights that the investment in robotic automation can yield returns of 10-20 times the initial costs within a few years. Firms can achieve this by lowering error rates and improving product consistency, which ultimately reduces waste and rework expenses.

**Tip:** Companies considering automation should also explore financing options, as many lenders offer tailored solutions for investing in robotic technology, enabling manufacturers to spread out costs while reaping the benefits of increased efficiency.

Cost Reduction in Manufacturing through Robotics

Innovative Applications of Robotics in Various Industries

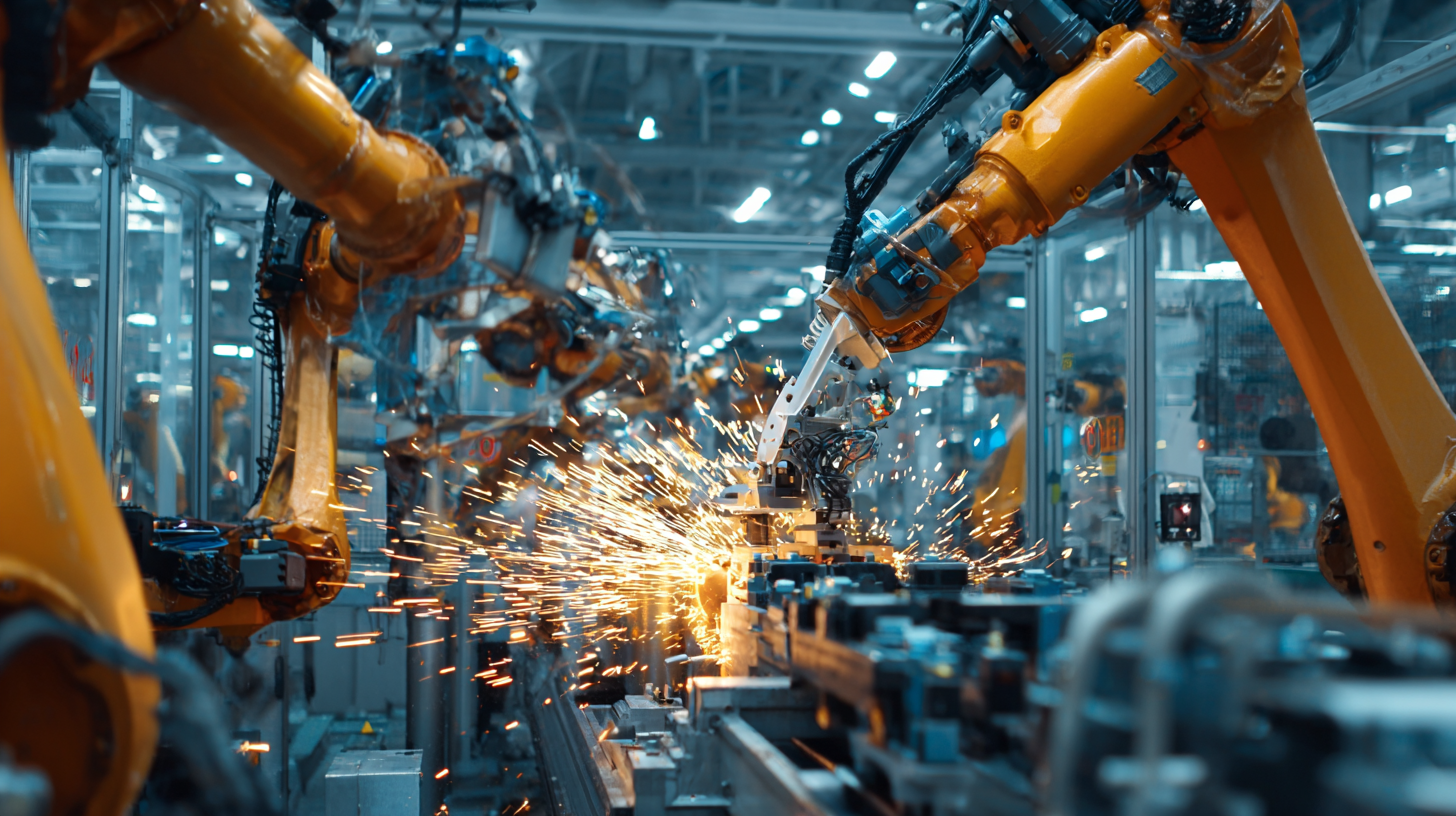

The integration of industrial robotics is transforming manufacturing across diverse sectors, from automotive to pharmaceuticals. In the automotive industry, robots are employed in assembly lines to enhance productivity and safety. They handle delicate tasks such as welding and painting with precision, reducing human error and increasing output rates. Additionally, collaborative robots, or cobots, are working alongside human operators, providing assistance and improving workflows in areas where human dexterity is needed.

In the realm of food production, robotics play a pivotal role in automating packaging and quality inspection processes. These machines can rapidly scan products for defects, ensuring that only the best quality items reach consumers. Moreover, in the healthcare industry, robots are revolutionizing logistics by managing inventory and facilitating the safe transport of medical supplies. This automation not only streamlines operations but also minimizes risks associated with human handling, ultimately leading to improved patient care. As industries continue to evolve, the innovative applications of robotics will likely redefine established practices, paving the way for greater efficiency and reliability.

Revolutionizing Manufacturing: How Industrial Robotics Are Shaping the Future of Automation

| Industry | Application | Benefits | Robot Type |

|---|---|---|---|

| Automotive | Welding and assembly | Increased precision and speed | Articulated robots |

| Electronics | Pick and place | Higher throughput and reduced errors | SCARA robots |

| Food & Beverage | Packaging | Improved hygiene and safety | Delta robots |

| Textiles | Sewing automation | Reduced labor costs | Collaborative robots |

| Pharmaceuticals | Lab automation | Enhanced accuracy and compliance | Robotic arms |

Future Trends: The Evolution of Robotics and Automation Technologies

The evolution of robotics and automation technologies is driving an unprecedented transformation in the manufacturing sector. According to a report by the International Federation of Robotics (IFR), the global stock of operational industrial robots reached 3 million units in 2020, with projections estimating that this number will exceed 6 million by 2024. This surge signifies not only the increasing adoption of robotics in various industries but also reflects the growing need for efficiency and precision in manufacturing processes.

Emerging trends in robotics, such as collaborative robots (cobots), advanced artificial intelligence, and the Internet of Things (IoT), are reshaping the landscape of automation technologies. A study by McKinsey highlights that up to 60% of all occupations could have at least 30% of their activities automated by 2030.

This shift is not just about replacing human labor; rather, it's about augmenting human capabilities, improving safety, and maximizing productivity. As companies invest in these advanced technologies, we can expect a future where human-robot collaboration becomes standard practice, leading to smarter and more adaptive manufacturing environments.

Related Posts

-

The Rapid Growth of Industrial Robotics Revolutionizing Manufacturing with 80 Percent Productivity Increase

-

Exploring the Future of Manufacturing Robots in Smart Factories

-

Revolutionizing Manufacturing: How Pick and Place Robots Optimize Efficiency by 30% in Production Lines

-

Maximizing Efficiency with Modern Gantry Systems: Key Trends and Innovations Shaping the Industry Today