Revolutionizing Automation: How Cartesian Robots Shape the Future of Precision Engineering

In the ever-evolving landscape of precision engineering, automation plays a pivotal role in enhancing efficiency and accuracy. At the forefront of this revolution is the Cartesian robot, a remarkable innovation that has transformed the way industries approach manufacturing and assembly processes. With their straightforward design and exceptional flexibility, Cartesian robots are designed to operate along three linear axes—X, Y, and Z—allowing for precise movements and positioning that cater to various tasks, from simple pick-and-place operations to intricate machining processes.

As industries increasingly demand higher productivity levels and greater reliability, the adoption of Cartesian robots has accelerated. Their ability to integrate seamlessly into existing workflows not only reduces the risk of human error but also optimizes production timelines. Furthermore, the versatility of Cartesian robots enables them to be programmed for a wide range of applications, making them indispensable tools in sectors such as electronics, automotive, and pharmaceuticals. This article delves into the transformative impact of Cartesian robots on precision engineering, showcasing how these machines are setting the stage for a future defined by unparalleled accuracy and efficiency in automation.

The Role of Cartesian Robots in Precision Engineering: Redefining Industry Standards

Cartesian robots are poised to redefine industry standards in precision engineering through their unmatched accuracy and versatility. According to a recent report by Research and Markets, the global Cartesian robot market is expected to grow at a CAGR of 9.2% from 2021 to 2026, reaching a valuation of over $5 billion. This growth is largely driven by the increasing demand for automation solutions that require high precision and repeatability in applications such as assembly, packaging, and material handling.

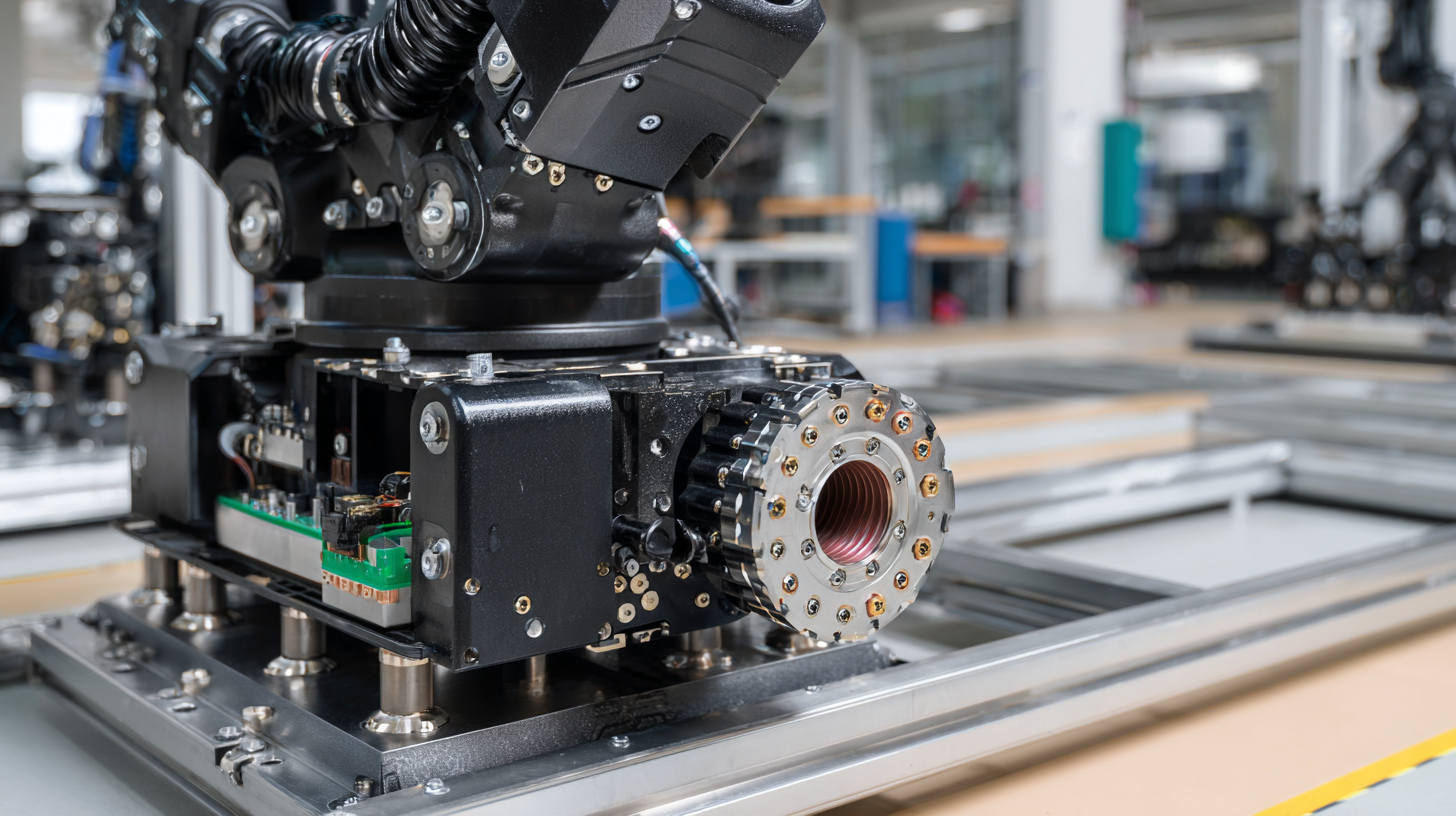

The unique design of Cartesian robots, featuring linear actuators that move along perpendicular axes, allows for exceptional speed and precision in operations. A study by the International Federation of Robotics highlights that these robots achieve positioning accuracy within ±0.1 mm, making them ideal for intricate tasks in manufacturing and quality control processes. With the rise of Industry 4.0, the integration of Cartesian robots into smart factories facilitates real-time data collection and analysis, further enhancing operational efficiencies and driving down production costs. As industries continue to seek innovative solutions for precision engineering challenges, Cartesian robots are set to become an indispensable component of the modern manufacturing landscape.

Key Advantages of Cartesian Robots in Automation: Efficiency and Accuracy Metrics

Cartesian robots, renowned for their linear movement across three axes, offer significant advantages in automation that directly enhance efficiency and accuracy in precision engineering. Their design allows for precise positioning and repeatability, which is crucial in various applications, including manufacturing, assembly, and quality control. By minimizing the complexities associated with multi-axis robotic systems, Cartesian robots eliminate many common errors, resulting in improved production rates and reduced waste.

In addition to their straightforward mechanics, Cartesian robots can operate at high speeds while maintaining accuracy. This capability enables them to execute tasks such as packaging and palletizing with remarkable precision, ultimately increasing throughput in production lines. The ease of programming and integration into existing systems further boosts their appeal. Automation with Cartesian robots not only enhances operational efficiency but also facilitates real-time monitoring and adjustments, ensuring that operations remain within desired accuracy metrics. This combination of speed and precision positions Cartesian robots as a transformative force in the landscape of modern automation.

Key Advantages of Cartesian Robots in Automation

Market Trends: Cartesian Robot Adoption Rates in Precision Engineering (2023 Data Analysis)

The adoption rates of Cartesian robots in precision engineering have seen a significant uptick in 2023, reflecting their growing importance in various manufacturing processes. Industries that prioritize accuracy and efficiency, such as electronics assembly and automotive production, have increasingly integrated these robots into their workflows. The ability of Cartesian robots to perform repetitive tasks with exceptional precision makes them an indispensable asset in today’s competitive market. With advancements in technology, these robots are becoming more affordable and easier to program, making them accessible to a wider range of businesses.

Market analysis reveals that companies are investing heavily in automation solutions, forecasting a continued rise in the deployment of Cartesian robots. As manufacturers strive to enhance productivity and reduce operational costs, the versatility of Cartesian robots allows for seamless integration into existing systems. The demand for customizability in production lines pushes manufacturers to adopt these flexible robotic systems, which can be tailored to specific tasks, thereby driving the overall growth of the market. With these trends, Cartesian robots are poised to redefine precision engineering and set new standards in automation efficiency.

Impact of Cartesian Robotics on Manufacturing Costs and ROI in Precision Engineering

The impact of Cartesian robotics on manufacturing costs and ROI in precision engineering is profound, as these systems offer unmatched accuracy and efficiency in production processes. By utilizing linear movements along three axes, Cartesian robots can perform repetitive tasks with minimal human intervention, significantly reducing labor costs and minimizing the potential for human error. This automation not only speeds up production cycles but also enhances product quality, leading to reduced waste and rework, thereby driving down overall manufacturing expenses.

Moreover, the implementation of Cartesian robots provides manufacturers with a compelling return on investment (ROI). Initial costs associated with acquiring and integrating these robotic systems are quickly offset by the long-term savings in labor and increased throughput. Additionally, the flexibility of Cartesian robots allows for easy reprogramming and adaptation to new production lines, further amplifying their economic benefits. As industries increasingly seek to optimize efficiency, the integration of Cartesian robotics stands out as a key factor in positioning businesses for sustained growth and competitiveness in the ever-evolving landscape of precision engineering.

Future Innovations in Cartesian Robotics and Their Potential Influence on Precision Engineering

The future of precision engineering is set to be transformed by innovations in Cartesian robotics. These robots, characterized by their simple, linear movements across the X, Y, and Z axes, are increasingly becoming integral to manufacturing processes that demand high accuracy and repeatability. According to a report by industry analysts, the global Cartesian robot market is expected to exceed $5 billion by 2025, as companies seek to enhance operational efficiency and reduce production costs. With the incorporation of advanced AI technologies, these robots are evolving, enabling smarter automation solutions that adapt in real-time to changing production demands.

In addition to their conventional applications, the rise of humanoid robots also suggests a compelling trend in the automation landscape. Market projections indicate that the humanoid robot sector could reach over $13 billion by 2028, primarily influenced by rapid advancements in artificial intelligence and a growing need for robots that can interact more naturally with human workers. The blending of Cartesian robotics with these innovations promises a future where precision engineering benefits not only from increased productivity but also from enhanced collaboration between machines and humans, ultimately reshaping the dynamics of the workforce.

Revolutionizing Automation: How Cartesian Robots Shape the Future of Precision Engineering

| Dimension | Details |

|---|---|

| Type of Cartesian Robot | 3-Axis, 4-Axis, 5-Axis |

| Key Features | High Precision, High Speed, Repeatability |

| Common Applications | Assembly, Welding, Packaging, CNC Machining |

| Technological Innovations | AI Integration, Enhanced Sensors, IoT Connectivity |

| Impact on Precision Engineering | Increased Efficiency, Cost Reduction, Enhanced Quality Control |

| Future Trends | Collaborative Robots, Customizable Solutions, Sustainability Focus |

Related Posts

-

Exploring the Future of Manufacturing: The Rise of Cartesian Robots in Automation

-

Exploring the Future of Manufacturing Robots in Smart Factories

-

Revolutionizing Manufacturing: How Pick and Place Robots Optimize Efficiency by 30% in Production Lines

-

The Rapid Growth of Industrial Robotics Revolutionizing Manufacturing with 80 Percent Productivity Increase

-

Revolutionizing Manufacturing: How Industrial Robotics Are Shaping the Future of Automation

-

Revolutionizing Efficiency: How Automated Storage Solutions Are Shaping the Future of Warehousing