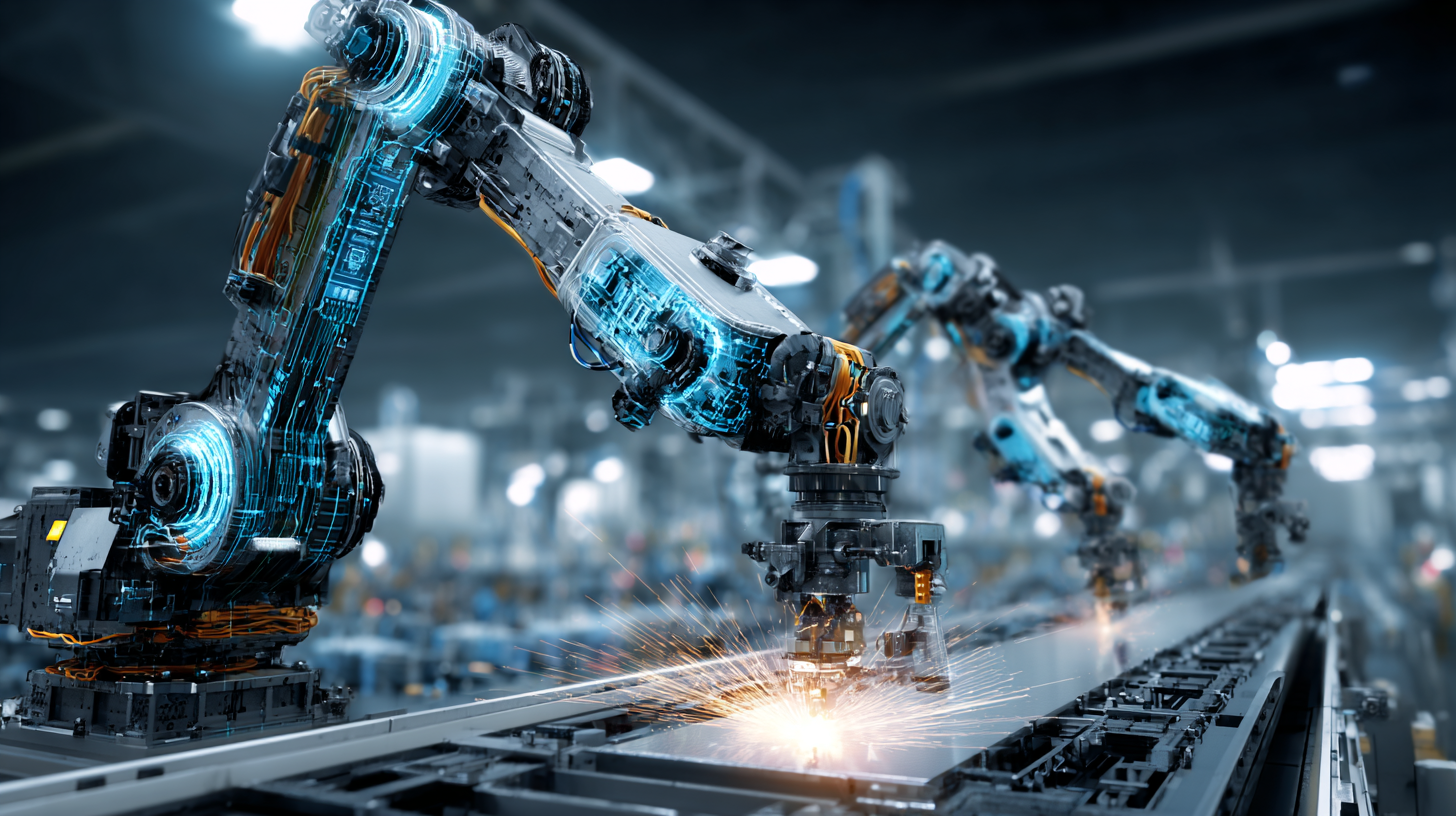

The Rapid Growth of Industrial Robotics Revolutionizing Manufacturing with 80 Percent Productivity Increase

The rapid growth of industrial robotics is transforming the manufacturing landscape, driving productivity levels to unprecedented heights. According to a report by the International Federation of Robotics, the global market for industrial robots is projected to reach a staggering $70 billion by 2025, reflecting an annual growth rate of over 20%. This surge is fueled by the increasing demand for automation to enhance efficiency, improve safety, and reduce costs in manufacturing processes. In fact, industries that have adopted industrial robotics have reported productivity increases of up to 80%, significantly outpacing their non-automated counterparts. As manufacturers face the pressures of globalization and ever-evolving market demands, the integration of industrial robotics is not just a competitive advantage but a critical necessity for survival and growth in the industry.

The Evolution of Industrial Robotics: A Historical Perspective

The evolution of industrial robotics has been a transformative journey, beginning in the mid-20th century with the introduction of the first robotic arms. In 1961, Unimate, the first industrial robot, was deployed in General Motors factories, performing tasks that were deemed hazardous for human workers. This innovation marked the start of a new era in manufacturing, where automation began to take hold and reshape production processes.

Over the decades, advancements in technology have led to a significant increase in the capabilities of industrial robots. According to a report by the International Federation of Robotics (IFR), the global stock of operational industrial robots surpassed 3 million units by 2022, reflecting a compound annual growth rate of approximately 12%. This growth is largely driven by sectors such as automotive, electronics, and consumer goods, where precision, speed, and efficiency are paramount. Furthermore, a study by McKinsey suggests that the integration of robotics in manufacturing could lead to productivity gains of up to 80%, supporting the need for companies to invest in these innovative solutions to remain competitive in an increasingly automated landscape.

Key Technologies Driving the Surge in Industrial Robot Adoption

The rise of industrial robotics is significantly transforming the manufacturing landscape, driven by several key technologies that enhance productivity and efficiency. Advances in artificial intelligence (AI) are at the forefront, enabling robots to learn from their environments and improve their performance over time. This adaptability allows for more precise operations, reducing errors and downtime while optimizing workflow processes. Furthermore, the integration of machine learning algorithms empowers robots to perform complex tasks that were once thought to be the exclusive domain of human workers.

Additionally, innovations in sensor technology play a crucial role in the increased adoption of industrial robots. These sensors provide real-time data and feedback, allowing robots to make informed decisions autonomously. Coupled with enhanced connectivity through the Internet of Things (IoT), manufacturers can achieve seamless communication between machines, leading to smarter production lines. The combination of AI and sophisticated sensor systems not only boosts operational efficiency but also paves the way for more flexible and responsive manufacturing environments, where robots can swiftly adapt to changing demands.

Quantifying Productivity: Analyzing the 80% Increase in Manufacturing Output

The integration of industrial robotics into manufacturing processes has led to an unprecedented surge in productivity, evidenced by a remarkable 80% increase in output. According to a report from the International Federation of Robotics (IFR), the global stock of industrial robots reached approximately 3 million units in 2022, a number projected to grow at an annual rate of 12%. This dramatic rise reflects a growing reliance on automation to enhance efficiency, reduce cycle times, and ultimately output.

Specific sectors have particularly benefited from this automation wave. For example, the automotive industry, as highlighted in a study by McKinsey & Company, reports that manufacturers utilizing advanced robotics have decreased production time by 30% while simultaneously increasing production quality. Furthermore, a survey conducted by Deloitte indicates that companies implementing robotic solutions are achieving a return on investment (ROI) of up to 300% within just a few years. As manufacturers continue to harness the power of robotics, the landscape of production is shifting towards smarter, more efficient operations that capitalize on technology to drive significant gains in productivity.

The Impact of Industrial Robotics on Manufacturing Productivity

This chart illustrates the significant increase in manufacturing output attributed to the implementation of industrial robotics. The data shows a consistent trend of productivity enhancement over the past five years.

Case Studies: Industries Transforming Through Robotics Integration

The integration of robotics in manufacturing is rapidly transforming the industry, significantly boosting productivity. Recent case studies across various sectors illustrate this trend. For instance, the automotive industry has seen the implementation of collaborative robots (cobots) that work alongside human operators, enhancing efficiency and flexibility on the production line. Reports indicate that companies utilizing these advancements witness productivity increases of up to 80%. This revolutionary approach not only streamlines operations but also fosters a safer work environment by minimizing human error and occupational hazards.

In logistics and supply chain management, the adoption of AI-powered robotics is equally impactful. Companies that embrace these technologies are finding innovative solutions to optimize inventory management and reduce operational costs. A systematic review reveals that the transition from Industry 4.0 to Industry 6.0 emphasizes the need for smart automation, indicating that businesses must adapt to ensure competitive advantage in a fast-evolving marketplace.

**Tips:** To stay ahead, businesses should invest in training programs for employees to effectively work alongside robots. Additionally, monitoring emerging AI technologies will help identify opportunities to further enhance productivity and streamline processes. Engaging in pilot programs can also allow companies to assess the potential benefits before a full-scale implementation.

The Rapid Growth of Industrial Robotics Revolutionizing Manufacturing with 80 Percent Productivity Increase

| Industry | Productivity Increase (%) | Robots Integrated | Annual Cost Savings ($) |

|---|---|---|---|

| Automotive | 85 | 1200 | $10,000,000 |

| Electronics | 78 | 800 | $7,500,000 |

| Consumer Goods | 80 | 600 | $5,000,000 |

| Food Processing | 82 | 400 | $4,000,000 |

Future Trends: The Next Frontier in Manufacturing Automation and Robotics

As the manufacturing sector continues to evolve, the integration of advanced robotics is poised to redefine the landscape of automation. Future trends indicate a significant shift towards

collaborative robots, or cobots, designed to work alongside human operators. These cobots enhance productivity while ensuring safety, creating a more efficient workflow on the factory floor.

Moreover, the rise of artificial intelligence in robotics is enabling machines to learn and adapt to various tasks, allowing for unprecedented flexibility and efficiency in manufacturing processes.

Another key trend is the increasing adoption of the Internet of Things (IoT) in industrial robotics. By connecting machines and devices through the IoT, manufacturers can achieve

real-time monitoring and data analysis, significantly improving operational efficiency.

Predictive maintenance powered by IoT technology not only reduces downtime but also optimizes the entire production line.

In summary, the future of manufacturing automation looks bright with the promise of smarter, more adaptable robots and interconnected systems that drive productivity to new heights.