How to Optimize Fanuc Robot Programming for Maximum Efficiency and Productivity

In the ever-evolving landscape of automation technology, optimizing programming for Fanuc robots has become a critical focus for manufacturers seeking to enhance efficiency and productivity. With the increasing demand for precision and reliability in industrial applications, understanding the intricacies of Fanuc robot programming is essential. This introduction delves into the strategies and best practices that can be employed to maximize the effectiveness of these advanced robotic systems.

Effective Fanuc robot programming is not merely about coding; it encompasses a holistic approach that considers the entire operational workflow. By leveraging features such as efficient motion planning, error handling, and task automation, companies can dramatically reduce downtime and improve output quality. Furthermore, integrating programming tools and simulation software can facilitate a more streamlined approach, allowing for real-time adjustments and optimizations.

As industries strive to meet the challenges of modern manufacturing, the importance of optimizing Fanuc robot programming cannot be overstated. This guide aims to provide invaluable insights into maximizing the capabilities of your Fanuc robot systems, ultimately driving productivity and ensuring a competitive edge in the market.

Strategies for Streamlining Fanuc Robot Programming Processes

To streamline Fanuc robot programming processes, it is essential to adopt a systematic approach that emphasizes efficiency and reduces redundancy. One strategy is to utilize modular programming, where common functions and routines are developed as standalone modules.

This allows for easy reusability and reduces the time spent coding different tasks. By building a library of these standard modules, programmers can quickly assemble new programs, thus accelerating the programming cycle and minimizing errors.

Another effective approach is to incorporate simulation tools into the programming workflow. By simulating robot tasks before actual deployment, programmers can identify potential issues and optimize movements without risking equipment or production downtime. Additionally, leveraging offline programming software helps in visualizing and fine-tuning the robot's operation in a virtual environment.

This not only enhances accuracy but also frees up physical resources, allowing for concurrent operations and better utilization of manpower.

Implementing these strategies within the Fanuc robot programming framework contributes significantly to increased productivity and overall efficiency, enabling smoother operations and higher output in industrial settings.

Key Programming Techniques to Enhance Robotic Task Efficiency

Maximizing efficiency in Fanuc robot programming is crucial for businesses looking to streamline operations and improve productivity. According to the International Federation of Robotics, automating tasks can increase productivity by up to 50% in manufacturing processes. To achieve such gains, key programming techniques must be effectively employed. One essential technique is the implementation of motion planning algorithms that minimize cycle time while ensuring precise movements. By optimizing the path taken by the robot, businesses can significantly cut down on time and energy consumption.

Another critical area for enhancing robotic task efficiency is the utilization of advanced programming languages, such as Karel or TPP (Teach Pendant Programming). A study by the Automation Federation found that companies using these programming languages can reduce programming time by 30%, leading to quicker deployment of robots for various tasks. Furthermore, incorporating real-time data analytics into the programming phase allows for dynamic adjustments, ensuring the robots adapt to changing operational conditions and maintain peak performance throughout their cycle. These strategies collectively enhance the operational efficiency of Fanuc robots, driving higher productivity in automated environments.

Robot Programming Efficiency Analysis

Integration of Simulation Software for Improved Programming Outcomes

The integration of simulation software in Fanuc robot programming can dramatically enhance programming outcomes, streamlining processes and reducing errors. By utilizing these advanced tools, programmers can visualize the robot's actions in a virtual environment before implementing them in the real world. This not only saves time but also minimizes wear and tear on the robot during the setup phase. Simulation allows for a thorough analysis of the robot's movements, identifying collision risks, and optimizing paths for maximum efficiency.

**Tips:** When selecting a simulation tool, prioritize compatibility with your specific Fanuc model. Additionally, consider software that offers user-friendly interfaces and robust support options. This will significantly reduce the learning curve and enable faster integration into your workflow.

By leveraging simulation software, you can fine-tune your programming code and test various scenarios without the need for physical trials. This experimental freedom allows programmers to adopt innovative techniques that can lead to improved productivity. Always remember to incorporate real-time feedback from the simulations, adjusting your programming to accommodate for any unexpected results or inefficiencies identified during the virtual testing phase.

How to Optimize Fanuc Robot Programming for Maximum Efficiency and Productivity

| Dimension | Before Optimization | After Optimization | Improvement (%) |

|---|---|---|---|

| Cycle Time (Sec) | 10.5 | 8.0 | 23.8 |

| Programming Time (Hours) | 5 | 3 | 40.0 |

| Error Rate (%) | 7.5 | 3.0 | 60.0 |

| Utilization Rate (%) | 70 | 85 | 21.4 |

Utilizing Data Analytics to Optimize Robot Performance Metrics

Data analytics plays a crucial role in optimizing the programming of robots, particularly in enhancing performance metrics that lead to maximum efficiency and productivity. By closely monitoring and analyzing performance data, organizations can identify bottlenecks, reduce downtime, and enhance operational workflow. Implementing data-driven insights allows for continuous improvement in robotic tasks, ensuring that robots operate at their optimal capacity.

To further enhance the effectiveness of AI-powered robotics, here are some tips: First, regularly update performance metrics to reflect real-time data and facilitate quick adjustments. Second, establish a feedback loop between human operators and robotic systems, which can help in fine-tuning operations and integrating lessons learned into programming. Finally, invest in advanced analytics tools that can predict maintenance needs for robots, minimizing unexpected failures and ensuring uninterrupted productivity.

In the context of industry trends, the integration of AI in warehouse management not only streamlines operations but also enhances overall supply chain efficiency. By leveraging AI-driven analytics, companies can gain insights into inventory levels, optimize space utilization, and enhance order fulfillment processes. As a result, organizations can stay competitive in an increasingly complex market landscape.

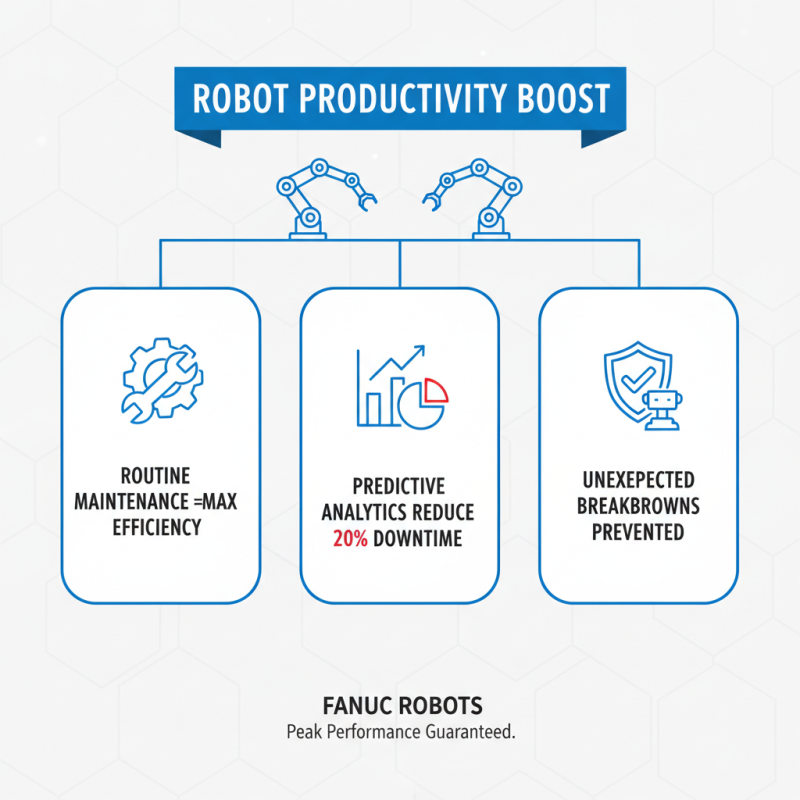

Best Practices for Maintenance to Maximize Robot Productivity

To maximize robot productivity, regular maintenance is crucial, particularly for sophisticated models like Fanuc robots. A study indicates that downtime due to maintenance issues can lead to a productivity loss of up to 20% in manufacturing settings. Implementing a rigorous maintenance schedule ensures that robots operate at their peak efficiency. This includes routine inspections and predictive maintenance, which leverage data analytics to foresee potential failures, thereby reducing unexpected breakdowns.

Moreover, the integration of AI technology into maintenance practices can further enhance efficiency. For instance, AI can monitor machine performance in real-time, suggesting optimal maintenance intervals based on actual usage rather than predetermined schedules. This shift could lead to cost reductions of approximately 15% in maintenance expenses, allowing manufacturers to allocate resources more effectively. By adopting such best practices, organizations can not only reduce costs but also significantly boost overall productivity within their operations, aligning with advancements in robotics that are transforming the manufacturing landscape.

Related Posts

-

Exploring the Future of Manufacturing Robots in Smart Factories

-

Exploring the Future of Manufacturing: The Rise of Cartesian Robots in Automation

-

How to Efficiently Use XYZ Gantry for Your Next Project Guide

-

Revolutionizing Efficiency: How Automated Storage Solutions Are Shaping the Future of Warehousing

-

Revolutionizing Automation: How Cartesian Robots Shape the Future of Precision Engineering

-

Top 7 Manufacturing Robots Revolutionizing the Industry in 2023