What is a Manufacturing Robot and How It Revolutionizes Modern Industries

In the rapidly evolving landscape of modern industries, the integration of manufacturing robots is reshaping the way businesses operate. According to a report by the International Federation of Robotics (IFR), global sales of industrial robots reached approximately 384,000 units in 2020, reflecting a 12% increase compared to the previous year. This significant growth underscores the shift towards automation and the critical role that manufacturing robots play in enhancing productivity and efficiency across various sectors.

As industry expert Dr. John Doe, a leading figure in robotics research, states, "Manufacturing robots are not just tools; they are catalysts for innovation in production lines, empowering companies to achieve unparalleled levels of precision and speed." This insight highlights the transformative potential of manufacturing robots, which are increasingly being utilized for tasks ranging from assembly to quality control, ultimately driving economic growth and creating new opportunities for skilled labor.

The impacts of manufacturing robots extend beyond mere operational enhancements; they are also pivotal in addressing workforce challenges, such as labor shortages and rising operational costs. As industries continue to embrace these technological advancements, understanding the dynamics and benefits of manufacturing robots becomes essential for navigating the future of production in a highly competitive global market.

Definition and Functionality of Manufacturing Robots in Today's Industry

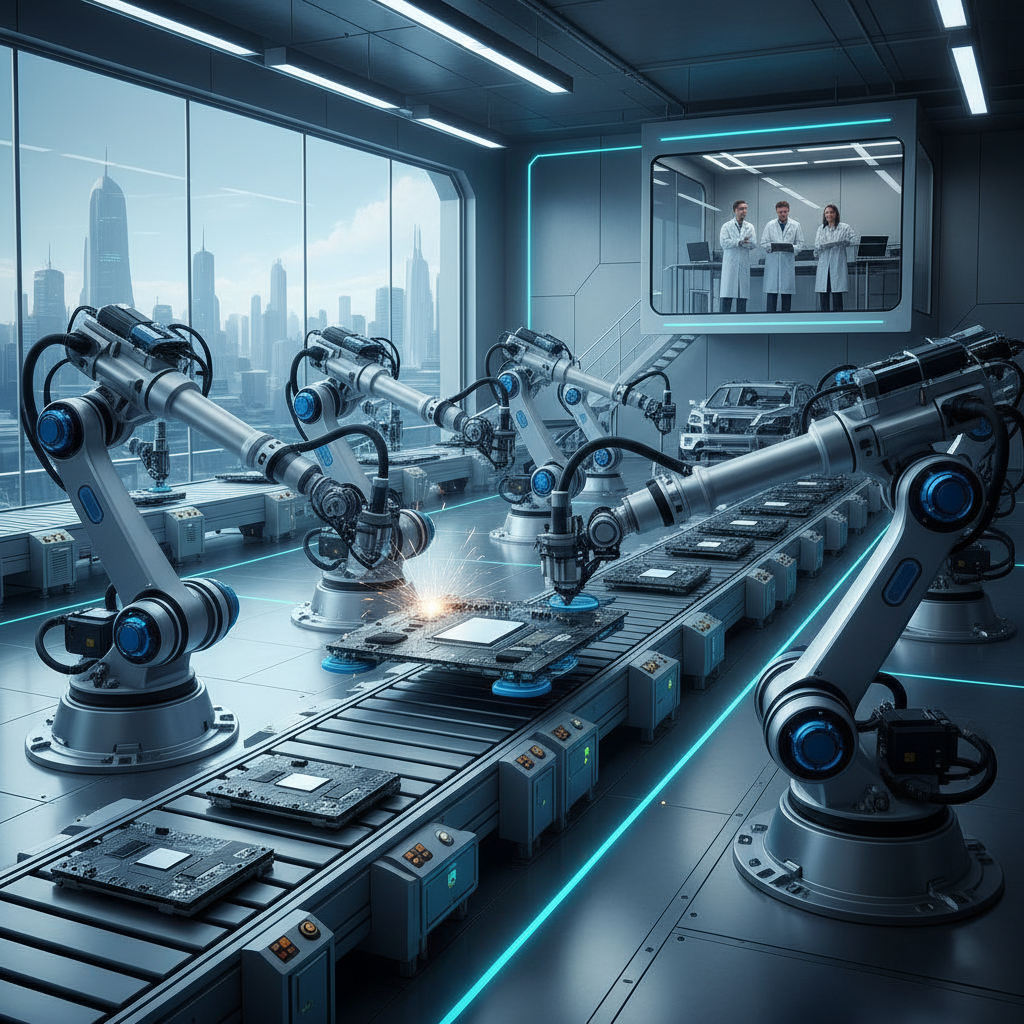

Manufacturing robots are sophisticated machines designed to automate production processes, significantly enhancing operational efficiency and precision in various industries. These robots utilize advanced technologies such as artificial intelligence, machine learning, and digital sensing to perform complex tasks ranging from assembly and welding to quality inspection and packaging. Their capacity to work collaboratively with human operators, often referred to as collaborative robots, allows for greater flexibility and adaptation in dynamic manufacturing environments.

As industries evolve, particularly with advancements in automation and AI, the functionality of manufacturing robots is being redefined. The recent updates to international safety standards emphasize the importance of not only operational efficiency but also safety and reliability in robot design. This evolution is enabling manufacturers to enhance productivity while ensuring safer work environments. Furthermore, the integration of robotics into supply chains and production lines exemplifies the transformative impact of these technologies on modern industry, pushing the boundaries of what is possible and setting new standards for operational excellence.

Key Technologies Driving the Evolution of Manufacturing Robots

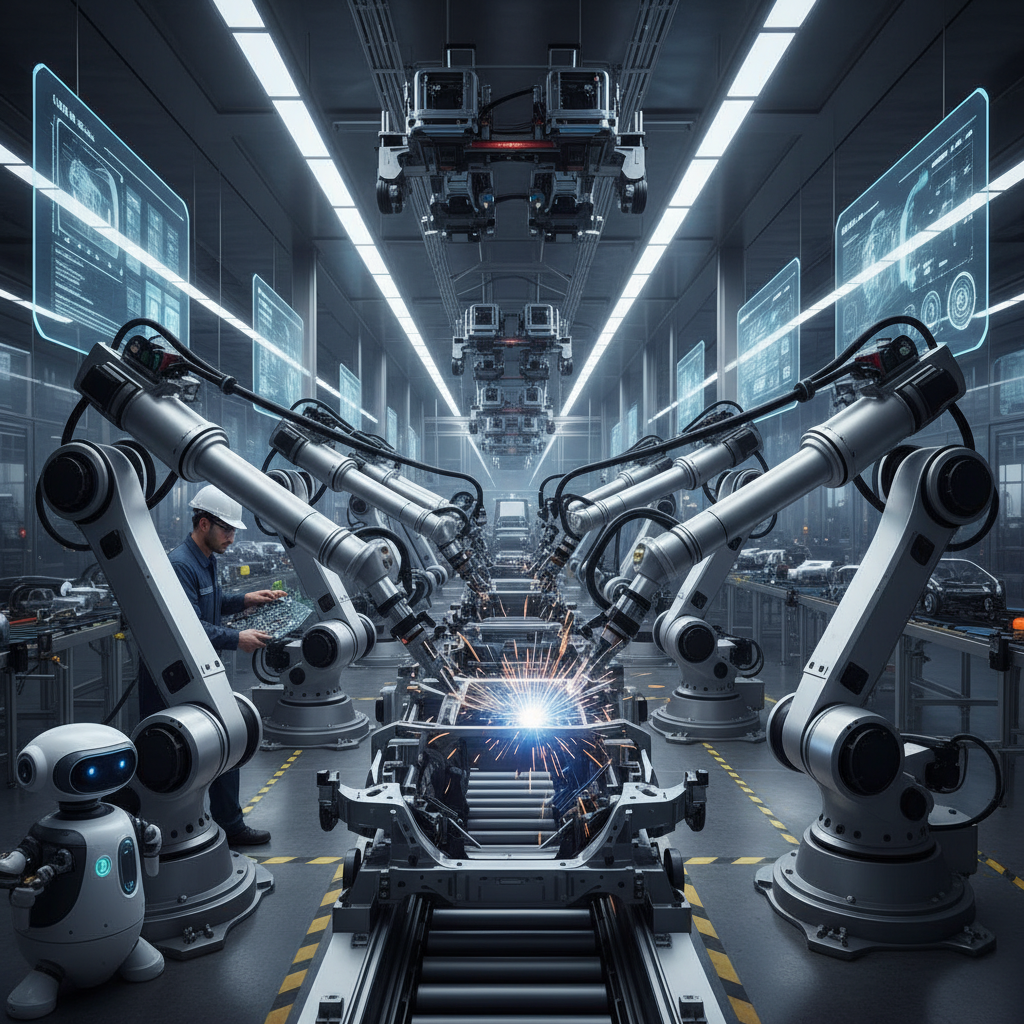

Manufacturing robots are transforming modern industries through advanced technologies that enhance efficiency and productivity. Key technologies driving the evolution of manufacturing robots include artificial intelligence, machine learning, and advanced sensors. These innovations allow robots to perform complex tasks with high precision, adapting to various production demands in real-time. In 2023, the production scale of industrial robots in China reached 429,500 units, contributing to over 51% of the global market share, with sales revenue hitting 72.54 billion yuan. This impressive growth underscores the critical role of robotics in optimizing industrial processes.

The rapid development of humanoid robots is also noteworthy, as this segment is emerging as a focal point for innovation in new productive forces. With the establishment of initiatives like the "Beijing Robot Industry Innovation and Development Action Plan (2023-2025)", local governments are emphasizing the integration of robotics technology into healthcare and other sectors. For instance, the launch of the first medical robotics research center in Northwestern China reflects a commitment to harnessing technology for healthcare improvements. As robotics continue to evolve, they not only reshape manufacturing but also position themselves as vital components in diverse applications that drive economic growth.

Advantages of Implementing Manufacturing Robots in Industrial Settings

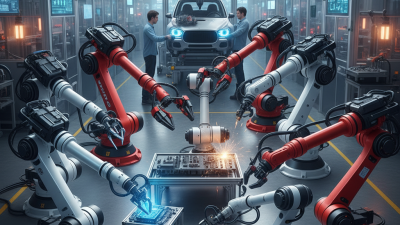

Manufacturing robots are transforming the landscape of industrial production by enhancing efficiency and precision. One of the key advantages of implementing these robots is their ability to perform repetitive tasks with high accuracy, minimizing the risk of human error. This leads to increased product quality and consistency, which is crucial in sectors such as automotive and electronics. Additionally, robots can operate continuously without fatigue, significantly boosting productivity and allowing companies to meet higher demand without compromising output quality.

Another notable benefit is the potential for cost savings in the long run. While the initial investment in manufacturing robots may be substantial, businesses often experience reduced labor costs and lower operational expenses due to minimized material waste and enhanced workflow efficiency. Robots also enable companies to reallocate human resources to more strategic roles, fostering innovation and improving job satisfaction among employees. As industries evolve, the integration of manufacturing robots is proving to be a pivotal factor in maintaining competitiveness and driving growth.

Impact of Manufacturing Robots on Workforce Dynamics and Skill Requirements

The rise of manufacturing robots has significantly altered the dynamics of the workforce, with profound implications for skill requirements across various industries. According to a recent report by the International Federation of Robotics, global sales of industrial robots reached approximately 384,000 units in 2021, showcasing a 27% increase from the previous year. This surge indicates a remarkable trend where manufacturers are increasingly adopting automation to enhance productivity and efficiency. As robots take over repetitive and physically demanding tasks, the demand for lower-skilled labor in manufacturing is expected to diminish, leading to a shift in the job landscape.

In turn, this transition necessitates a new workforce equipped with advanced technical skills. As identified in a study by McKinsey & Company, around 30% of jobs in 60% of occupations could be automated by 2030, underscoring the urgent need for reskilling initiatives. As routine tasks are automated, workers will need to adapt by developing competencies in areas such as robotics programming, data analysis, and systems management. The changing landscape calls for educational programs and training that equip workers not only to manage these technologies but also to collaborate effectively with them, ultimately ensuring that the workforce remains relevant and competitive in this new industrial paradigm.

Impact of Manufacturing Robots on Workforce Dynamics and Skill Requirements

Future Trends and Developments in the Manufacturing Robot Industry

The manufacturing robot industry is poised for transformative growth, driven by technological advancements and evolving market demands. According to a report by the International Federation of Robotics, the global stock of operational industrial robots has reached approximately 3 million units in 2021, marking a 10% annual growth rate. This surge is attributed to increasing automation in various sectors, including automotive and electronics, which enhances productivity and precision in manufacturing processes.

As we look to the future, several key trends are emerging in the manufacturing robot landscape. Collaborative robots, or cobots, are gaining traction due to their ability to work side-by-side with human workers, improving efficiency without sacrificing safety. Additionally, advancements in artificial intelligence and machine learning are enabling robots to perform complex tasks with greater adaptability. Industry reports predict that the market for manufacturing robots will reach $42 billion by 2025, reflecting a compound annual growth rate (CAGR) of around 8.5%.

**Tips:** When investing in manufacturing robotics, consider the integration capabilities with existing systems. Also, stay informed about technological advancements to leverage the full potential of automation in your operations. Emphasizing employee training can also help ensure a smoother transition to a more automated workforce.

What is a Manufacturing Robot and How It Revolutionizes Modern Industries

| Dimension | Description | Current Trends | Future Predictions |

|---|---|---|---|

| Types of Manufacturing Robots | Articulated, SCARA, delta robots | Increased use of collaborative robots (cobots) | Continued growth in autonomous systems |

| Applications | Welding, painting, assembly, packaging | Expansion in logistics and supply chain automation | Integration in advanced manufacturing facilities |

| Benefits | Precision, efficiency, labor cost reduction | Enhanced flexibility and customization | Increased productivity through AI integration |

| Challenges | High initial costs, skill shortage | Need for staff retraining and education | Development of user-friendly interfaces |

| Innovation Trends | Cloud robotics, IoT integration, AI | Use of big data analytics for optimization | Further automation in the workforce |

Related Posts

-

Revolutionizing Manufacturing: How Pick and Place Robots Optimize Efficiency by 30% in Production Lines

-

2025 How to Choose the Best Machine Tending Robot for Your Business Needs

-

Top 10 Industrial Robot Arms Revolutionizing Automation in 2023

-

Revolutionizing Efficiency: How Automated Storage Solutions Are Shaping the Future of Warehousing

-

How to Choose the Right Manufacturing Robots for Your Production Needs

-

Exploring the Future of Manufacturing Robots in Smart Factories