Why You Should Invest in a Pick and Place Robot for Your Assembly Line Efficiency

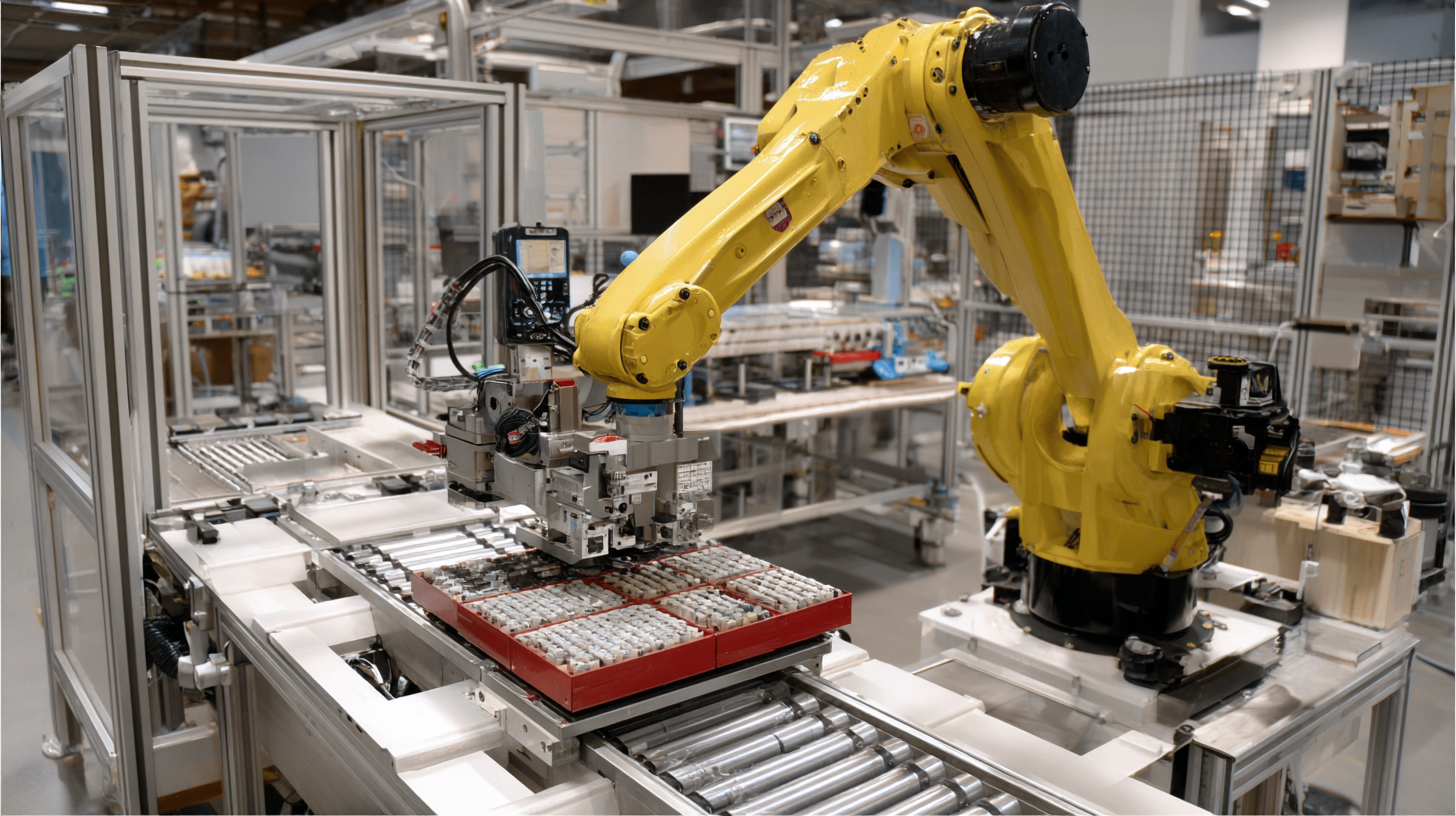

In today's rapidly evolving manufacturing landscape, the efficiency of assembly lines is paramount to maintaining a competitive edge. The integration of technology has become essential, and one of the most effective solutions is the implementation of a pick and place robot. According to Dr. Emily Carter, a renowned robotics expert and author of "Automating the Future," “Investing in a pick and place robot not only streamlines processes but also significantly reduces the chances of human error.” This reflects the critical importance of automation in enhancing productivity and reliability in assembly operations.

As industries strive to optimize their workflows, the benefits of adopting a pick and place robot extend far beyond mere efficiency. These robotic systems are designed to handle complex tasks with remarkable precision, enabling manufacturers to focus on value-added activities instead of repetitive labor. By incorporating pick and place robots into assembly lines, companies can achieve increased throughput and reduced operational costs, allowing for greater flexibility in production schedules.

Furthermore, the scalability of pick and place robots means that businesses can easily adjust their operations to meet changing demands. With customizable configurations and advanced programming capabilities, these robots can adapt to various tasks, making them an indispensable asset for any forward-thinking manufacturer. As we delve into why investing in pick and place robots is crucial for enhancing assembly line efficiency, it becomes clear that the future of manufacturing hinges on smart automation solutions.

Benefits of Pick and Place Robots in Modern Assembly Lines

In today's fast-paced manufacturing landscape, pick and place robots have emerged as invaluable assets to enhance assembly line efficiency. These robots streamline the process of moving components from one location to another, minimizing the time it takes to assemble products. With their high-speed operation and precision, they reduce cycle times significantly, allowing manufacturers to meet increasing demands without compromising on quality.

Moreover, the integration of pick and place robots leads to a reduction in labor costs. By automating repetitive and labor-intensive tasks, companies can allocate their human workforce to more complex roles that require critical thinking and problem-solving skills. Additionally, these robots are equipped with advanced vision systems, enabling them to adapt to various tasks and handle delicate components without the risk of damage. This adaptability not only increases productivity but also enhances overall workplace safety by minimizing the risk of human error in assembly processes.

Why You Should Invest in a Pick and Place Robot for Your Assembly Line Efficiency - Benefits of Pick and Place Robots in Modern Assembly Lines

| Benefit | Description | Impact on Efficiency | Cost Savings |

|---|---|---|---|

| Increased Speed | Pick and place robots can operate at high speeds, reducing cycle time for assembly. | Up to 50% faster assembly processes. | Reduction in labor costs due to faster production times. |

| Precision and Accuracy | Robots minimize human error, leading to higher quality products. | Decreased rejection rates by 20%. | Lower costs associated with defective products. |

| Flexibility | Can be programmed for multiple tasks with simple adjustments. | Quick transition between different products reduces downtime. | Lower costs through reduced need for additional machinery. |

| Safety | Reduces the risk of workplace injuries by taking over hazardous tasks. | Improved workplace safety records. | Potential reduction in insurance and compensation costs. |

| 24/7 Operation | Robots can work continuously without breaks. | Maximized throughput increases overall production capacity. | Increased output leads to better return on investment. |

Key Features to Look for in 2025's Top Pick and Place Robots

When considering investing in a pick and place robot for your assembly line, it’s crucial to focus on key features that will enhance efficiency in 2025’s market. First, precision is paramount. According to a report by MarketsandMarkets, the demand for precision robotics is expected to increase by 20% annually, as manufacturers seek to minimize errors that lead to costly product rework. Look for robots with advanced vision systems that enable them to locate and handle components with exceptional accuracy.

Additionally, adaptability is vital. The robotics sector is rapidly evolving, with flexible automation becoming a necessity. A study by Deloitte predicts that businesses utilizing adaptive and programmable robots will boost production rates by up to 30%. Therefore, selecting pick and place robots that can easily switch between tasks and handle various types of materials will provide a competitive edge.

Tip: Always consider robots with user-friendly interfaces and integration capabilities with existing systems. This will not only simplify the training process for staff but also ensure a seamless transition toward automating your assembly line, boosting overall productivity in the long run. Look for options that include real-time monitoring and analytics to optimize performance over time.

Cost-Effectiveness: ROI on Investing in Pick and Place Automation

Investing in pick and place robots for your assembly line is not only a strategic move towards enhancing efficiency but also a significant opportunity for cost-effectiveness. According to a report by the International Federation of Robotics (IFR), the market for industrial robots, including pick and place automation, is expected to grow by 12% annually through 2025. This growth reflects the increasing recognition of the return on investment (ROI) that these robots can offer. Automation reduces labor costs and minimizes human error, leading to higher consistency in product quality. One case study reported that manufacturers saw up to a 30% reduction in assembly time after integrating pick and place solutions.

Furthermore, a McKinsey & Company report highlights that companies investing in automation technologies can achieve ROI rates of over 200% within three years. By streamlining the assembly process and allowing for faster production cycles, businesses can respond more effectively to market demands. The upfront costs of purchasing and implementing a pick and place robot can be quickly offset by savings in labor and increases in output, demonstrating that these technologies are not just a trend but a viable long-term investment for enhancing operational efficiency.

Future Trends in Robotics That Will Enhance Assembly Line Efficiency

The assembly line landscape is undergoing a radical transformation driven by advancements in robotics. Future trends indicate that the integration of artificial intelligence (AI) and machine learning algorithms into pick and place robots is set to revolutionize efficiency. According to a recent report by Markets and Markets, the global robotics market is expected to reach $210.3 billion by 2025, growing at a CAGR of 26.9%. This growth is largely attributed to the demand for automation in manufacturing processes, where pick and place robots play a pivotal role in boosting productivity and reducing labor costs.

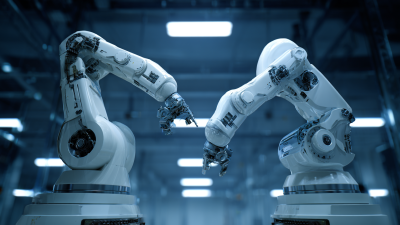

Moreover, the implementation of collaborative robots (cobots) alongside traditional pick and place systems is gaining traction. Cobots can work alongside human workers, enhancing operational flexibility without the need for extensive safety precautions. The International Federation of Robotics projects that by 2023, the market for cobots will exceed 1 million units annually. This increases the potential for assembly lines to not only improve efficiency but also enhance the overall quality of output. With investing in these technologies, businesses can position themselves at the forefront of an evolving industry, ultimately leading to greater competitiveness and profitability.

Success Stories: Companies Revolutionizing Operations with Pick and Place Robots

As companies increasingly turn to automation, the integration of pick and place robots is transforming operations across various sectors. Success stories abound, demonstrating how businesses have revolutionized their assembly lines by adopting these intelligent machines. For instance, in fulfillment warehouses, partnerships aimed at integrating advanced pick-and-place robotics have accelerated efficiency, highlighting how these technologies meet the demands of a fast-paced market.

In flexible manufacturing, collaborative robots are enhancing productivity through adaptive automation. By integrating artificial intelligence, these cobots can work alongside human employees, optimizing workflows and improving accuracy. Companies are witnessing substantial improvements as they leverage AI-driven solutions, reshaping their operational landscapes and enabling seamless adaptation to changing consumer needs.

In flexible manufacturing, collaborative robots are enhancing productivity through adaptive automation. By integrating artificial intelligence, these cobots can work alongside human employees, optimizing workflows and improving accuracy. Companies are witnessing substantial improvements as they leverage AI-driven solutions, reshaping their operational landscapes and enabling seamless adaptation to changing consumer needs.

Tips: When considering the implementation of pick and place robots, assess your current workflow to identify bottlenecks that automation can resolve. Start with pilot projects to evaluate technology effectiveness, ensuring a smooth transition. Finally, invest in training programs for staff to facilitate collaboration between humans and robots, maximizing the potential of your new systems.

Related Posts

-

Exploring the Future of Manufacturing: The Rise of Cartesian Robots in Automation

-

How to Choose the Right Manufacturing Robots for Your Production Needs

-

Exploring the Future of Manufacturing Robots in Smart Factories

-

Revolutionizing Manufacturing: How Pick and Place Robots Optimize Efficiency by 30% in Production Lines

-

The Rapid Growth of Industrial Robotics Revolutionizing Manufacturing with 80 Percent Productivity Increase

-

Revolutionizing Manufacturing: How Industrial Robotics Are Shaping the Future of Automation