Top 10 Industrial Robot Arms Revolutionizing Automation in 2023

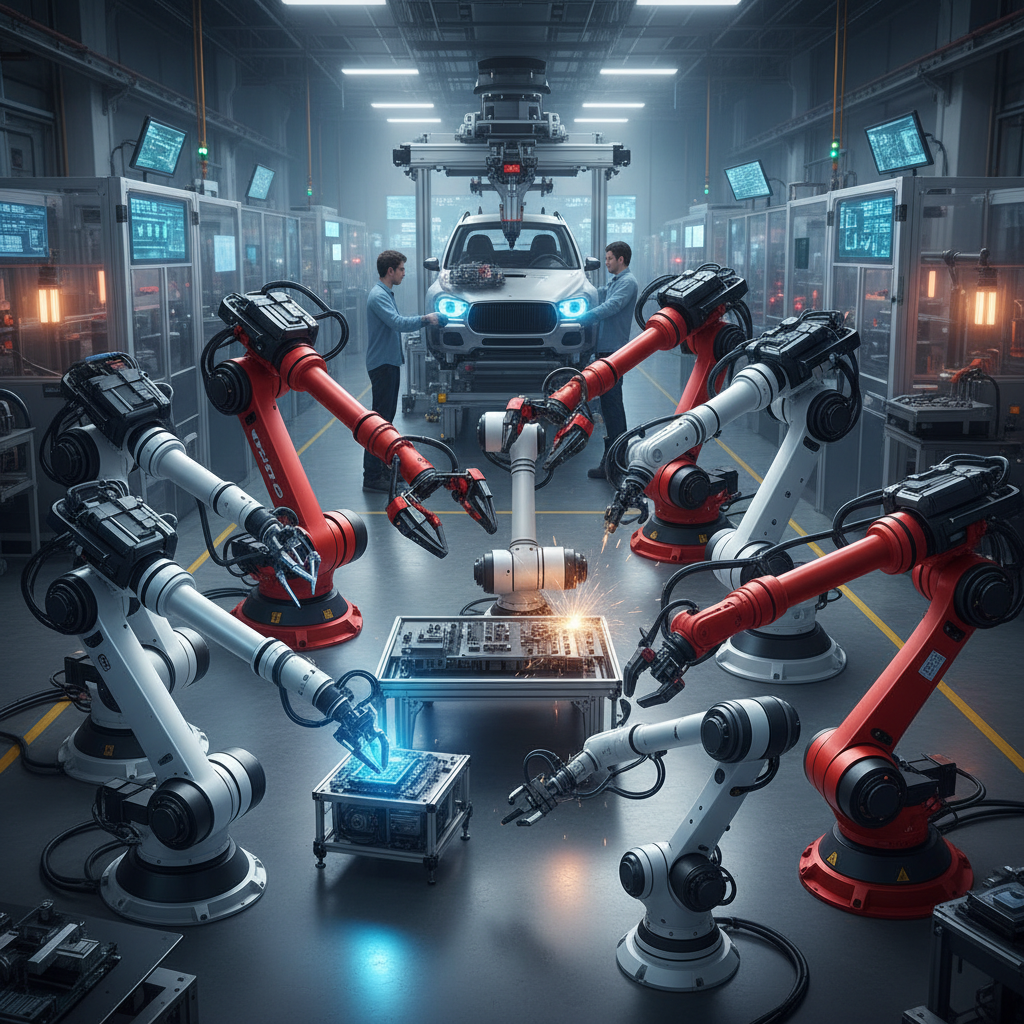

In 2023, the rapid evolution of automation technologies is significantly transforming industries, with industrial robot arms at the forefront of this revolution. According to a report by the International Federation of Robotics (IFR), global sales of industrial robots grew by 10% in 2022, with industrial robot arms accounting for a substantial portion of this growth. This surge is driven by the increasing demand for efficiency, precision, and safety in manufacturing processes. The implementation of advanced robotic technologies not only enhances productivity but also mitigates labor shortages that many industries face today.

As companies strive to maintain their competitive edge, investing in state-of-the-art industrial robot arms has become essential. Markets and Markets predicts that the industrial robot arm market will reach USD 39.84 billion by 2025, reflecting a compound annual growth rate (CAGR) of 10.4%. This growth is fueled by technological innovations such as artificial intelligence and machine learning, which allow these systems to perform complex tasks with unprecedented levels of autonomy and adaptability. In this article, we will explore the top 10 industrial robot arms that are revolutionizing automation in 2023, highlighting their capabilities and contributions to various sectors.

Understanding the Key Features of 2023's Leading Industrial Robot Arms

In 2023, industrial robot arms have undergone significant advancements, becoming essential tools in the realm of automation. One key feature of the leading models is their enhanced dexterity, allowing them to perform intricate tasks with precision. Robots like the collaborative robot arms (cobots) can now seamlessly interact with human workers, ensuring safety while boosting productivity in manufacturing environments. Their ability to adapt in real-time to the changing conditions of the assembly line is turning them into invaluable assets.

Another notable aspect is the integration of artificial intelligence and machine learning capabilities. These technologies enable robot arms to analyze vast amounts of data, learning from their environment and optimizing their performance over time. This self-improvement capability not only streamlines operations but also reduces downtime, as robots can predict and prevent potential failures before they happen. Additionally, increased connectivity through IoT devices allows for better monitoring and management, providing real-time insights into performance and efficiency, which are crucial for maintaining a competitive edge in the industry.

Comparing Efficiency and Versatility Among Top-Rated Robot Arms

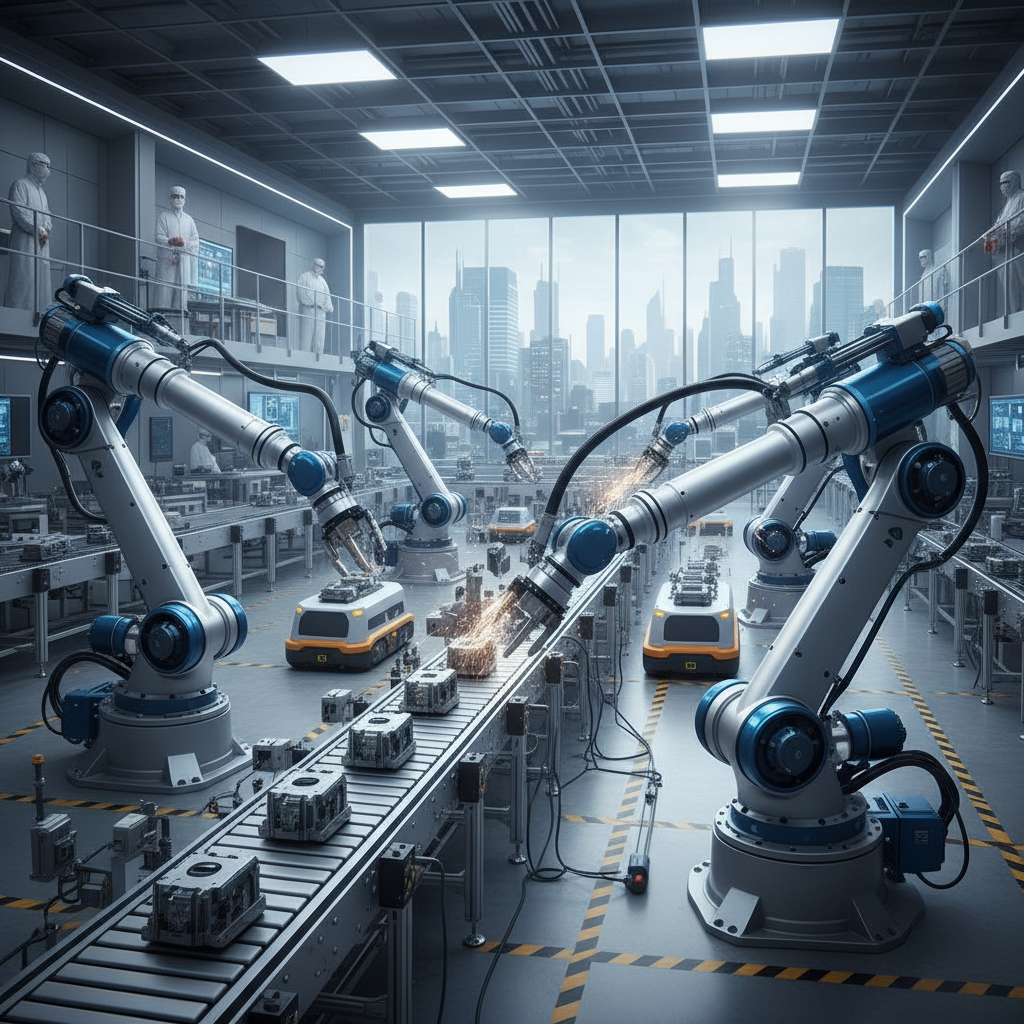

In 2023, the landscape of automation is markedly shaped by advancements in industrial robot arms, which are increasingly recognized for their efficiency and versatility. According to a recent report by ResearchAndMarkets, the global industrial robotics market is projected to reach $85 billion by 2027, highlighting the rising demand for innovative solutions in manufacturing and assembly processes. Particularly, robot arms are outperforming traditional systems in terms of productivity, achieving up to 50% more output while minimizing waste and downtime.

Among the leading contenders, the UR10e from Universal Robots stands out not only for its adaptability in diverse applications but also for its ease of integration into existing workflows. In studies conducted by McKinsey, companies that utilized collaborative robot arms reported a reduction in labor costs by nearly 25%, emphasizing the dual advantage of cost-effectiveness and enhanced operational capabilities. Moreover, the versatility of these arms allows them to seamlessly shift between tasks, making them a valuable asset in sectors ranging from automotive to consumer electronics. The relentless innovation in this field continues to push the boundaries of what's possible in automation, positioning robot arms at the forefront of industrial transformation.

Essential Integration Techniques for Maximizing Automation Potential

In 2023, the integration of industrial robot arms into manufacturing processes has reached new heights, making it essential to adopt robust techniques to maximize their potential. One of the key strategies involves ensuring seamless communication between robots and existing machinery. Utilizing open-source protocols can facilitate data exchange and enable real-time monitoring, which enhances operational efficiency. Manufacturers should prioritize interoperability, allowing robot arms to adapt and communicate with various systems on the floor, thus streamlining workflows.

Another critical technique for maximizing automation potential is the use of advanced programming environments that support artificial intelligence and machine learning. By implementing software that can learn and adapt to changing workflows, companies can position their robot arms to become more versatile and effective. This adaptability not only reduces downtime during reprogramming but also empowers businesses to tackle unique tasks with greater precision. Investing in continuous training and development of both the robot systems and the workforce involved is crucial for sustaining this transformation in automation and ensuring that organizations remain competitive in a rapidly evolving landscape.

Evaluating Cost-Effectiveness of the Latest Robot Arm Technologies

As industries continue to embrace automation, evaluating the cost-effectiveness of the latest robot arm technologies becomes crucial. Recent reports highlight that companies adopting advanced robotic solutions can achieve up to a 30% reduction in labor costs while increasing productivity by up to 60%. For instance, the implementation of collaborative robots (cobots) allows for seamless human-robot interaction, significantly lowering the barriers to entry for small and medium-sized enterprises looking to automate.

Investing in cutting-edge robot arms can also lead to enhanced precision and quality in manufacturing processes. According to a study by the International Federation of Robotics, the global industrial robot market is projected to grow by 13% annually, with innovations such as AI integration and improved sensors driving this growth. These advancements not only decrease operational costs in the long run but also maximize return on investment, making them an attractive option for businesses looking to stay competitive.

Tip: When considering robot arm technologies, it’s essential to conduct a thorough cost-benefit analysis that includes potential savings from decreased labor and improved output quality. Additionally, consider investing in training for your workforce to ensure a smooth transition to an automated setup.

Top 10 Industrial Robot Arms Cost-Effectiveness in 2023

This chart compares the cost-effectiveness of the top 10 industrial robot arms in 2023 based on their initial investment and operational efficiency.

Future Trends and Innovations in Industrial Robotics to Watch

In 2023, industrial robotics is witnessing groundbreaking innovations that are poised to redefine automation across various sectors. Investing in collaborative robots (cobots) is becoming a trend, with the International Federation of Robotics projecting a 27% annual growth rate for cobot shipments from 2022 to 2025. This surge is driven by advancements in AI and machine learning, enabling robots to adapt to complex tasks alongside human workers, thereby enhancing productivity and safety.

Moreover, the integration of IoT in robotic systems is facilitating real-time data analysis and predictive maintenance. According to a report by Robotics Business Review, the global market for IoT-enabled robotic systems is expected to reach $118 billion by 2026, showcasing the critical role that smart technology will play in future automation processes. Companies are increasingly looking to harness these technologies to streamline operations and reduce downtime, ensuring a competitive edge in a rapidly evolving marketplace.

Tips: When considering the adoption of industrial robots, evaluate your specific operational needs and explore options for integrating AI and IoT. Additionally, training staff on collaborative robotics can foster a safer and more productive work environment. Staying updated on market trends will also help you make informed decisions regarding technology investments in your business strategy.

Top 10 Industrial Robot Arms Revolutionizing Automation in 2023

| Rank | Robot Arm Model | Payload Capacity (kg) | Reach (mm) | Number of Axes | Key Features |

|---|---|---|---|---|---|

| 1 | Model A | 10 | 1200 | 6 | Resistant to dust, high precision |

| 2 | Model B | 15 | 1000 | 7 | Lightweight, energy-efficient |

| 3 | Model C | 20 | 1500 | 6 | Highly flexible, multi-tasking |

| 4 | Model D | 30 | 1800 | 7 | AI integrated, auto calibration |

| 5 | Model E | 25 | 1600 | 6 | Collaborative, safety features |

| 6 | Model F | 35 | 2000 | 8 | Advanced sensors, robust design |

| 7 | Model G | 40 | 2200 | 7 | User-friendly interface, modular design |

| 8 | Model H | 50 | 2400 | 6 | High-speed operation, endurance |

| 9 | Model I | 60 | 2500 | 7 | Remote operation, smart connectivity |

| 10 | Model J | 70 | 2600 | 6 | Intelligent learning, adaptive performance |

Related Posts

-

Exploring the Future of Manufacturing Robots in Smart Factories

-

Revolutionizing Manufacturing: How Pick and Place Robots Optimize Efficiency by 30% in Production Lines

-

The Rapid Growth of Industrial Robotics Revolutionizing Manufacturing with 80 Percent Productivity Increase

-

Revolutionizing Manufacturing: How Industrial Robotics Are Shaping the Future of Automation

-

Exploring the Future of Manufacturing: The Rise of Cartesian Robots in Automation

-

Revolutionizing Automation: How Cartesian Robots Shape the Future of Precision Engineering