Top 10 Fanuc Robot Applications in Manufacturing and Automation Industry

In the rapidly evolving landscape of manufacturing and automation, the integration of robotics has become a cornerstone for achieving operational excellence. A recent report by the International Federation of Robotics indicates that the global industrial robot market is projected to reach $70 billion by 2025, underscoring the growing importance of automation solutions in enhancing productivity and efficiency. Among the leaders in this sector, Fanuc robots have established themselves as a preferred choice for businesses looking to optimize their manufacturing processes and streamline operations.

According to industry expert Dr. James McMillan, who has been researching advancements in industrial automation for over a decade, "Fanuc robots stand out due to their versatility and reliability, making them essential tools in the modern manufacturing toolkit." This sentiment is echoed across various sectors, from automotive to electronics, where the deployment of Fanuc robots has led to significant reductions in cycle times and improved precision in assembly processes. As we delve into the top applications of Fanuc robots in the manufacturing domain, it becomes evident that these machines not only enhance productivity but also play a crucial role in redefining the future of industrial operations.

Overview of Fanuc Robots in Manufacturing and Automation

Fanuc robots have become pivotal in the manufacturing and automation sectors, revolutionizing traditional processes through enhanced efficiency and precision. These robotic systems are engineered to perform various tasks, including assembly, painting, material handling, and welding. Their ability to operate continuously and tirelessly allows manufacturers to maintain high productivity levels while reducing labor costs and minimizing human error. This technological advancement not only streamlines workflows but also enhances the overall quality of the final products, as robots maintain consistent performance and precision over time.

The versatility of Fanuc robots further extends to various industries, including automotive, electronics, and food processing. With advanced programming capabilities, they can adapt to different tasks and processes, making them indispensable in modern manufacturing. Additionally, the integration of robotics with artificial intelligence and machine learning enables smarter operations, allowing for real-time adjustments and optimizations. As industries continue to evolve, the role of robotic automation will undoubtedly expand, paving the way for smarter factories and more efficient production lines.

Top 10 Fanuc Robot Applications in Manufacturing and Automation Industry

| Application | Industry | Robot Type | Key Benefits |

|---|---|---|---|

| Welding | Automotive | Articulated Robots | High precision and repeatability |

| Material Handling | Manufacturing | SCARA Robots | Increased throughput and reduced labor costs |

| Pick and Place | Electronics | Delta Robots | Speed and flexibility in operations |

| Assembly | Consumer Goods | Collaborative Robots | Enhanced worker safety and productivity |

| Painting | Automotive | Articulated Robots | Consistent finish and reduced material waste |

| Inspection | Quality Control | Vision Systems | Early detection of defects and quality assurance |

| Packaging | Food and Beverage | Industrial Robots | Efficiency and better shelf-life |

| CNC Machining | Aerospace | Articulated Robots | Precision and complex part manufacturing |

| Education and Training | Academic Institutions | Collaborative Robots | Hands-on learning and skill development |

| R&D Prototyping | Various | Flexible Robots | Innovation and rapid prototyping capabilities |

Key Advantages of Using Fanuc Robots in Industry

The adoption of advanced robotics in the manufacturing and automation industries offers numerous key advantages that significantly enhance operational efficiency. One of the primary benefits is the increased precision and consistency robots provide in repetitive tasks. Unlike human labor, automated systems maintain high levels of accuracy, reducing the risk of errors that can lead to costly rework or product defects. This reliability allows manufacturers to uphold high-quality standards while optimizing their processes.

Another critical advantage is the ability to operate around the clock without fatigue. This characteristic enables companies to maximize production output and meet the demands of a fast-paced market. Robots can seamlessly execute tasks such as assembly, welding, and packaging, effectively filling labor gaps and enabling a more scalable workforce. Furthermore, the advanced technology incorporated in modern robotic systems allows for easy integration with existing manufacturing setups, paving the way for smoother transitions into more automated environments while minimizing disruptions to production schedules.

Top Applications of Fanuc Robots in Production Processes

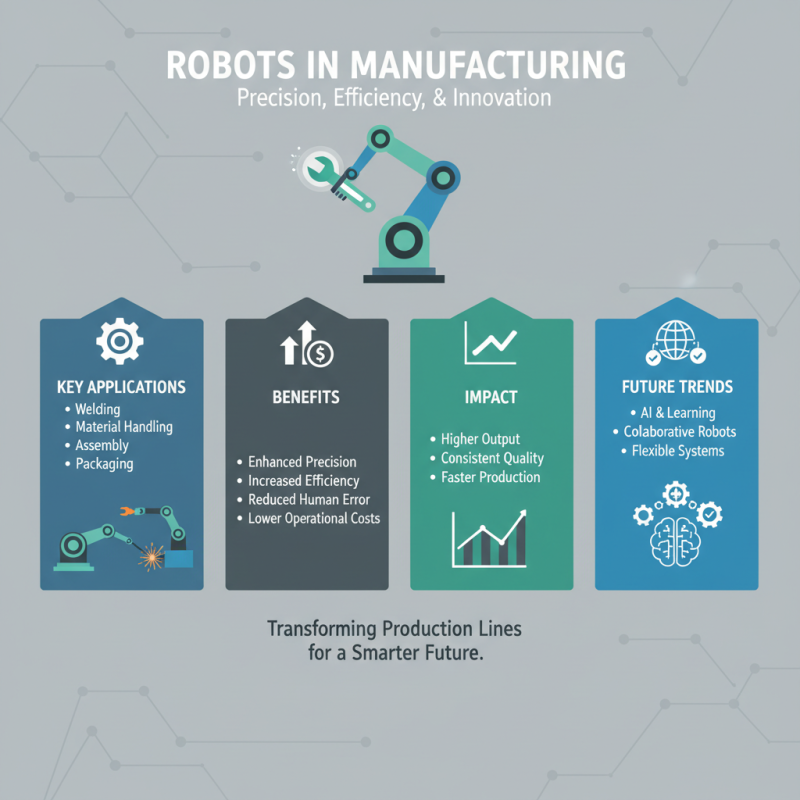

In the ever-evolving landscape of manufacturing and automation, robots have become indispensable assets, particularly in production processes. One of the most prominent categories of robots utilized is for tasks such as welding, material handling, assembly, and packaging. These applications not only enhance precision and efficiency but also significantly reduce human error and operational costs. By integrating robotics into production lines, manufacturers can achieve higher output while maintaining optimal quality standards.

When considering the implementation of robots in manufacturing, there are key tips to keep in mind. First, it's crucial to conduct a thorough analysis of your production workflow to identify pain points that automation could alleviate. Secondly, investing in flexible robotic systems can offer adaptability to changing production requirements, ensuring that you remain competitive in the market. Lastly, continuous training for staff on how to work alongside robots is essential for maximizing productivity and foster a seamless collaboration between humans and machines.

As automation becomes more prevalent, exploring the latest advancements in robotics technology can further enhance efficiency. This includes utilizing AI and advanced sensors, enabling robots to learn and adapt to various tasks. As a result, businesses can not only streamline their processes but also unlock the full potential of their production capabilities, making the leap into the future of manufacturing.

Case Studies: Successful Implementations of Fanuc Robots

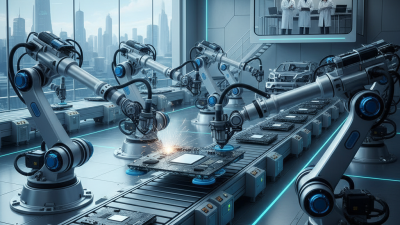

Fanuc robots have been instrumental in transforming manufacturing processes across various industries. One notable case study involves a leading automotive manufacturer that implemented robotics for assembly line automation. By integrating flexible robotic arms, the company significantly enhanced its production speed and accuracy. The robots efficiently handled tasks such as part assembly and quality inspections, resulting in a decrease in manual errors and a marked increase in overall throughput. This implementation not only boosted productivity but also reduced labor costs, showcasing the versatility of robotics in high-demand environments.

Fanuc robots have been instrumental in transforming manufacturing processes across various industries. One notable case study involves a leading automotive manufacturer that implemented robotics for assembly line automation. By integrating flexible robotic arms, the company significantly enhanced its production speed and accuracy. The robots efficiently handled tasks such as part assembly and quality inspections, resulting in a decrease in manual errors and a marked increase in overall throughput. This implementation not only boosted productivity but also reduced labor costs, showcasing the versatility of robotics in high-demand environments.

Another compelling example can be found in the electronics sector, where a major producer adopted robotic solutions for component handling and packaging. The deployment of collaborative robots allowed for smoother operations on the assembly line, as they could work alongside human operators without safety concerns. This collaboration led to a more streamlined workflow, minimizing downtime and ensuring consistent output quality. The successful integration of these systems illustrates how automation can optimize even the most intricate manufacturing tasks, ultimately contributing to improved efficiency and profitability for the organization.

Another compelling example can be found in the electronics sector, where a major producer adopted robotic solutions for component handling and packaging. The deployment of collaborative robots allowed for smoother operations on the assembly line, as they could work alongside human operators without safety concerns. This collaboration led to a more streamlined workflow, minimizing downtime and ensuring consistent output quality. The successful integration of these systems illustrates how automation can optimize even the most intricate manufacturing tasks, ultimately contributing to improved efficiency and profitability for the organization.

Future Trends in Fanuc Robotics within Manufacturing Sector

The future of robotics in the manufacturing sector is poised for transformative advancements, driven by the integration of artificial intelligence and machine learning technologies. As industries increasingly adopt automated solutions, the role of robotics will expand from simple, repetitive tasks to complex problem-solving applications. This shift will enable systems to learn from their environments, adapt to new scenarios, and even predict maintenance needs, thereby enhancing efficiency and productivity.

Moreover, the rise of collaborative robots, or cobots, signifies a pivotal trend in manufacturing. These robots are designed to work safely alongside human operators, facilitating a more flexible work environment where tasks are shared between machines and people. This collaboration can lead to more ergonomic workflows and reduced strain on human workers. The focus on customization and scalability of robotic solutions will empower manufacturers to respond quickly to market changes, ensuring that they remain competitive in the rapidly evolving landscape of industry 4.0.

Related Posts

-

How to Choose the Right Manufacturing Robots for Your Production Needs

-

Revolutionizing Manufacturing: How Industrial Robotics Are Shaping the Future of Automation

-

Exploring the Future of Manufacturing: The Rise of Cartesian Robots in Automation

-

Why You Should Invest in a Pick and Place Robot for Your Assembly Line Efficiency

-

Why Choose a Pick and Place Robot? Boost Efficiency with 70% Increased Productivity

-

What is a Manufacturing Robot and How It Revolutionizes Modern Industries