Exploring the Future of Manufacturing: The Rise of Cartesian Robots in Automation

In recent years, the manufacturing sector has undergone a significant transformation driven by advancements in automation technologies, notably the rise of the cartesian robot. These robots are renowned for their precision, speed, and ability to handle a variety of tasks, making them indispensable in modern production lines. According to a report by the International Federation of Robotics, the global market for industrial robots is projected to reach $70 billion by 2025, with cartesian robots playing a pivotal role due to their versatility and cost-effectiveness. As manufacturers seek to enhance operational efficiency and reduce labor costs, the adoption of cartesian robots is expected to surge, contributing to a more automated and streamlined production process. This increasing reliance on cartesian robots marks a significant shift in manufacturing paradigms, setting the stage for innovations that will reshape the industry landscape in the years to come.

The Evolution of Cartesian Robots in Modern Manufacturing

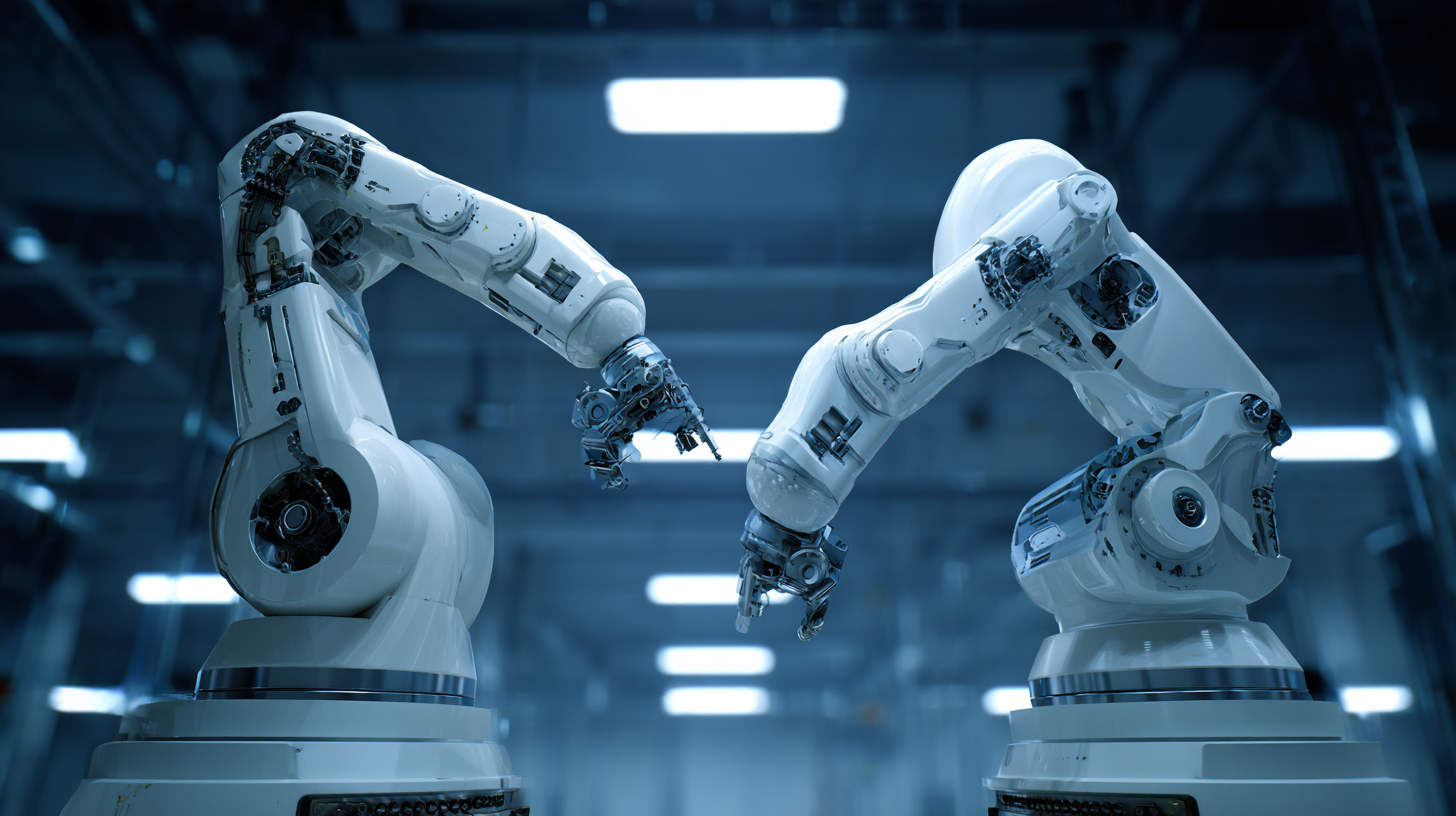

The evolution of Cartesian robots in modern manufacturing represents a significant leap forward in the automation landscape. These robots, characterized by their linear movement along three axes—X, Y, and Z—offer unparalleled precision and repeatability. Over the past few decades, advancements in materials, sensors, and control systems have allowed for the creation of increasingly sophisticated Cartesian robots. These machines are now capable of handling more complex tasks, from assembly and packaging to material handling, with greater efficiency than ever before.

The evolution of Cartesian robots in modern manufacturing represents a significant leap forward in the automation landscape. These robots, characterized by their linear movement along three axes—X, Y, and Z—offer unparalleled precision and repeatability. Over the past few decades, advancements in materials, sensors, and control systems have allowed for the creation of increasingly sophisticated Cartesian robots. These machines are now capable of handling more complex tasks, from assembly and packaging to material handling, with greater efficiency than ever before.

As industries strive for higher productivity and cost-effectiveness, the adaptability of Cartesian robots has become a key factor in their adoption. Their modular designs allow for easy integration into existing manufacturing processes, enabling companies to customize automation solutions according to their specific needs. Furthermore, the rise of Industry 4.0 has propelled Cartesian robots into the spotlight, with advancements in artificial intelligence and IoT technologies enhancing their operational capabilities. This integration supports smarter manufacturing environments, where robots can communicate and collaborate seamlessly with other machinery, leading to optimized workflows and reduced downtime.

Key Benefits of Integrating Cartesian Robots into Production Lines

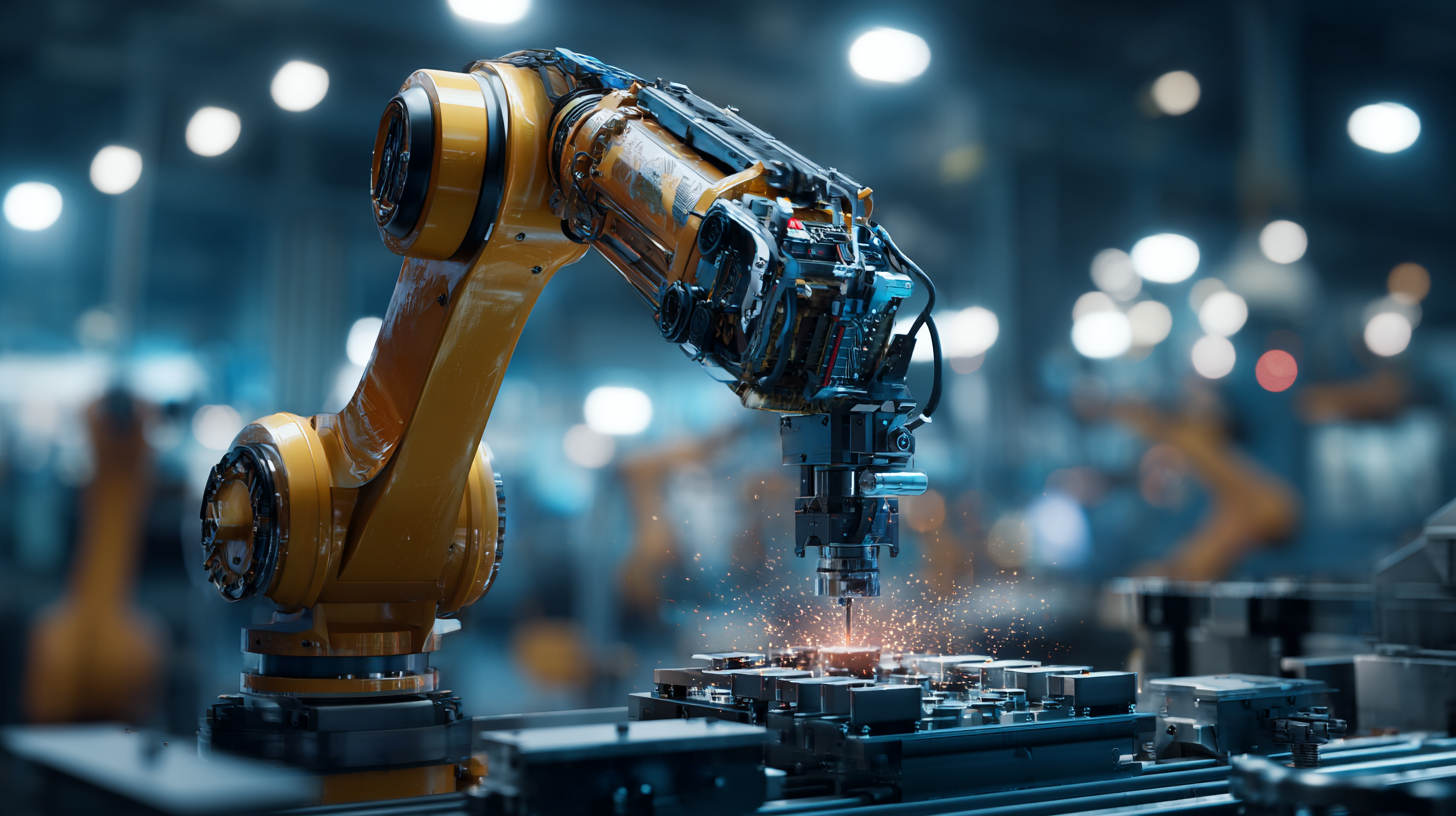

The integration of Cartesian robots into production lines is revolutionizing the manufacturing landscape. These robots, characterized by their linear motion along the X, Y, and Z axes, offer unparalleled precision and efficiency. One of the key benefits is the increase in productivity; Cartesian robots can operate continuously without breaks, significantly reducing cycle times and maximizing output. Their programmed capabilities allow for quick setup and reconfiguration, making it easier for manufacturers to adapt to changing production demands and product variations.

Moreover, Cartesian robots enhance the quality of finished products. Equipped with advanced sensors and feedback systems, they ensure that each movement is executed with accuracy, thereby minimizing defects and waste. This consistency not only boosts product quality but also leads to higher customer satisfaction. Additionally, their robust design and ability to handle a wide range of tasks—from assembly to packaging—make Cartesian robots a versatile solution for modern manufacturing facilities, streamlining operations and reducing overall operational costs. As the demand for automation grows, the advantages of Cartesian robots in production environments will become increasingly apparent.

Comparative Analysis: Cartesian Robots vs. Traditional Robots

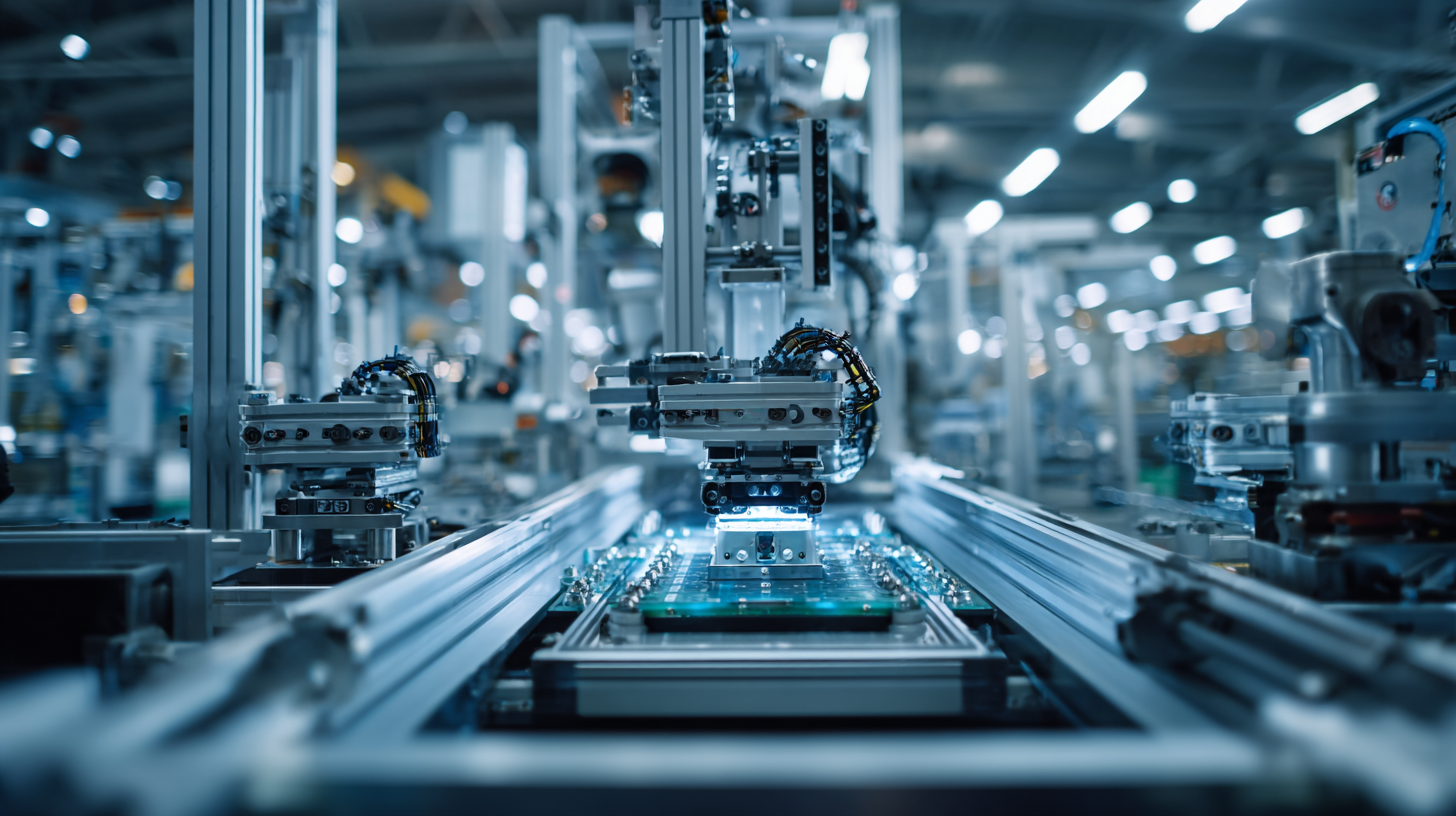

The rise of Cartesian robots signifies a pivotal shift in the manufacturing landscape, particularly when juxtaposed against traditional robot systems. Unlike traditional robots that often rely on complex jointed arms with multiple degrees of freedom, Cartesian robots operate on a simple linear axis mechanism. This straightforward design enables precise control and greater accuracy in tasks such as assembly, packaging, and material handling. Additionally, their ease of programming and integration into existing workflows make them an attractive option for industries looking to enhance efficiency and reduce operational costs.

**Tips:** When considering implementing Cartesian robots in your operations, assess the specific tasks at hand and match them with the strengths of this robotic system. For high-speed repetitive tasks, Cartesian robots can significantly minimize cycle times. Furthermore, ensure that there is adequate training for your team to maximize productivity and avoid potential operational hiccups.

Moreover, while traditional robots may offer versatility for complex applications, Cartesian robots excel in environments where precision and speed are paramount. Their scalability makes them ideal for manufacturers experiencing fluctuating production demands, allowing for quick adjustments and reconfigurations without extensive downtime. This adaptability positions Cartesian robots as a key player in the future of automated manufacturing.

**Tips:** Always conduct a thorough ROI analysis when transitioning to Cartesian robots to understand the long-term savings and productivity gains. Collaboration with robotics experts can also provide insights into optimizing robot placement and workflow.

Exploring the Future of Manufacturing: The Rise of Cartesian Robots in Automation - Comparative Analysis: Cartesian Robots vs. Traditional Robots

| Feature | Cartesian Robots | Traditional Robots |

|---|---|---|

| Degrees of Freedom | 3 | 6-7 |

| Speed | High | Moderate |

| Precision | Very High | High |

| Complexity of Programming | Low | High |

| Cost | Lower | Higher |

| Maintenance | Low | Moderate to High |

| Typical Applications | Pick and Place, Assembly | Welding, Painting, Heavy Load Handling |

Future Trends: How AI and IoT Are Shaping Cartesian Robotics

The integration of AI and IoT is revolutionizing the landscape of Cartesian robotics, particularly within the manufacturing sector. These technologies enhance the precision and adaptability of robots, enabling them to perform complex tasks with greater efficiency. As industries embrace automation, AI-driven robots can learn from their environments and optimize processes in real time, paving the way for increased productivity and reduced operational costs. This shift marks a significant advancement over traditional systems, which often lacked the intelligence to respond dynamically to changing conditions.

Moreover, the implications of these technologies extend beyond manufacturing. In agriculture, for example, IoT-enabled systems are being employed to detect and treat plant diseases, addressing critical challenges such as water shortages and sustainability. The growing demand for advanced robotics is reflected in projections indicating that the robotics market will burgeon to upwards of $375 billion by 2035. As industries across various sectors recognize the potential of AI and IoT integration, the future of Cartesian robotics appears not just promising, but transformative.

Challenges and Considerations in Adopting Cartesian Automation

The adoption of Cartesian robots in manufacturing technologies presents several challenges and considerations that organizations must navigate. According to a report by Market Research Future, the global industrial robotics market is projected to reach $119 billion by 2025, with Cartesian robots playing a significant role in this growth. However, businesses often face obstacles such as integration complexities with existing systems and the need for skilled personnel to oversee and maintain these automated solutions. Industry experts have noted that nearly 60% of small to mid-sized enterprises cite technical challenges as a major barrier to automation investments.

Furthermore, while the advantages of increased efficiency and precision are evident, companies must also consider the high initial costs associated with implementing Cartesian automation. A study by the International Federation of Robotics found that approximately 25% of companies delay their automation plans due to budgetary constraints and lack of clear ROI evidence. Additionally, workforce implications cannot be overlooked, as the introduction of automated technologies requires reskilling existing employees to handle new roles that may emerge. Thus, while the promise of enhanced productivity is significant, thorough planning and consideration are essential for a successful transition to Cartesian robotics in manufacturing.

Related Posts

-

Exploring the Future of Manufacturing Robots in Smart Factories

-

Revolutionizing Manufacturing: How Pick and Place Robots Optimize Efficiency by 30% in Production Lines

-

The Rapid Growth of Industrial Robotics Revolutionizing Manufacturing with 80 Percent Productivity Increase

-

Revolutionizing Manufacturing: How Industrial Robotics Are Shaping the Future of Automation

-

Revolutionizing Efficiency: How Automated Storage Solutions Are Shaping the Future of Warehousing

-

Maximizing Efficiency with Modern Gantry Systems: Key Trends and Innovations Shaping the Industry Today