How to Choose the Right Manufacturing Robots for Your Production Needs

In the ever-evolving landscape of modern production, selecting the right manufacturing robots is crucial for optimizing efficiency and productivity. As technology advances, the options available in the realm of manufacturing robots have expanded, presenting unique opportunities and challenges for businesses. According to industry expert Dr. Emily Zhang, a leading robotics engineer at the Robotics Institute, "Choosing the right manufacturing robots is not merely a technical decision; it requires a deep understanding of your specific production needs and goals."

As manufacturers face increasing pressure to enhance operational efficiency and reduce costs, understanding the capabilities and limitations of different types of manufacturing robots becomes essential. From collaborative robots (cobots) that work alongside human operators to heavy-duty industrial robots designed for high-volume tasks, each option serves distinct purposes within the production process. Evaluating factors such as workload, task complexity, and integration capabilities can significantly impact a company's overall performance and competitiveness in the market.

Ultimately, the decision to invest in manufacturing robots should align with both current production demands and future growth objectives. As businesses strive to innovate and adapt to changing market conditions, taking a strategic approach to selecting the right robotic solutions will pave the way for success in the age of automation.

Identifying Key Production Goals to Inform Robot Selection

When considering the integration of manufacturing robots into your production line, the first step is to clearly identify your key production goals. Understanding whether you aim to enhance efficiency, improve product quality, or reduce labor costs will significantly influence your robot selection. For example, if your primary goal is to increase throughput, you may require high-speed robots capable of handling various tasks such as assembly, packaging, or quality inspection.

In contrast, if precision is your main concern, then investing in collaborative robots (cobots) could be essential, as they are designed to work safely alongside human operators and excel at intricate operations.

Additionally, evaluating your production environment and scalability needs is crucial. If your manufacturing process is subject to frequent changes or seasonal fluctuations, opting for flexible robots that can be easily reprogrammed or reconfigured will be beneficial. It’s also important to consider the types of materials you handle and the specific applications, as these factors can dictate the types of grippers and end-effectors required. By aligning your robot selection process with your strategic production objectives, you can ensure a well-informed decision that ultimately enhances operational efficiency and meets your business demands.

Evaluating the Types of Manufacturing Robots Available in the Market

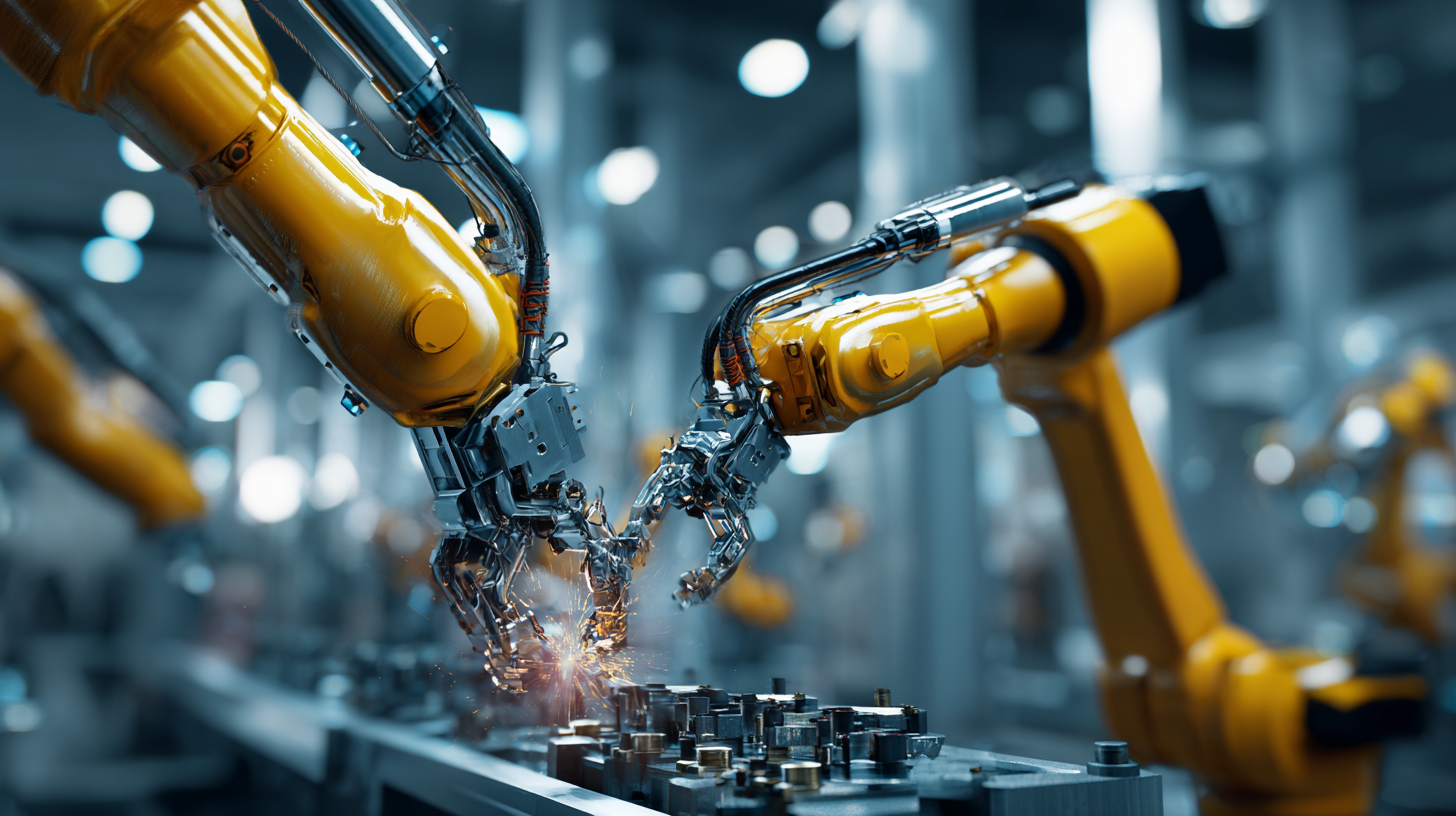

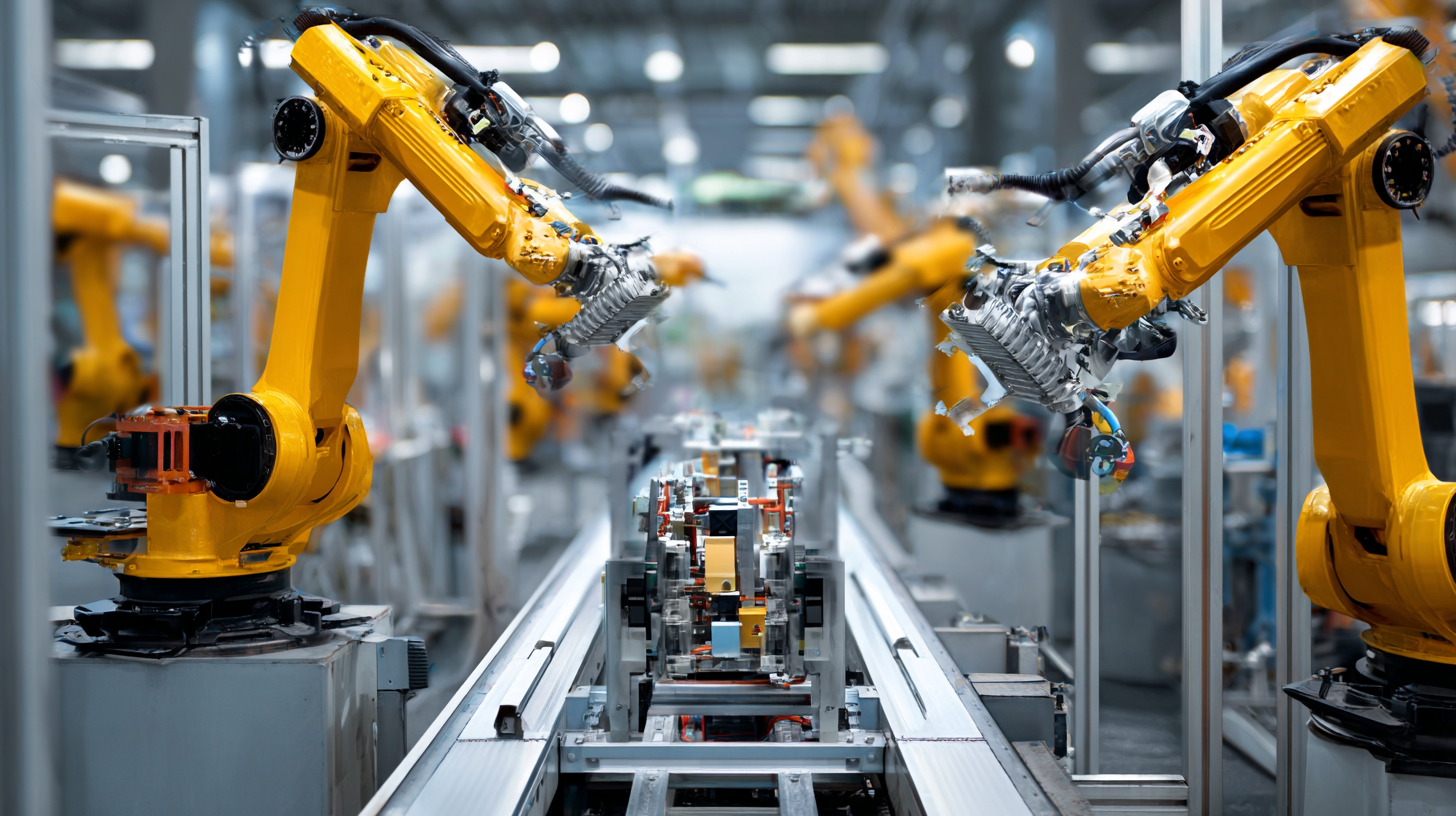

When choosing manufacturing robots for your production needs, it is vital to evaluate the various types of robots available in the market. Each type serves different purposes and brings unique advantages to manufacturing processes. For instance, industrial robots, which include articulated robots and SCARA robots, are renowned for their versatility and precision in tasks such as welding, assembly, and material handling. These robots are ideal for high-volume production environments where speed and accuracy are paramount.

Another category worth considering is collaborative robots, or cobots, which are designed to work alongside human operators. Cobots are typically easier to program and can adapt to various tasks, making them well-suited for smaller production runs and industries where flexibility is required. Additionally, specialized robots, like delta robots and gantry robots, provide distinct advantages for specific applications such as packaging and high-speed sorting. By carefully assessing your production requirements and understanding the strengths of each type of robot, you can make an informed decision that aligns with your operational goals.

How to Choose the Right Manufacturing Robots for Your Production Needs

| Robot Type | Payload Capacity | Reach | Precision | Application Area |

|---|---|---|---|---|

| Articulated Robots | Up to 100 kg | Up to 3.5 m | ± 0.1 mm | Welding, Assembly, Packaging |

| Collaborative Robots (Cobots) | Up to 16 kg | Up to 1.5 m | ± 0.1 mm | Pick and Place, Assembly |

| Delta Robots | Up to 2 kg | Up to 1.2 m | ± 0.5 mm | High-Speed Picking, Packing |

| SCARA Robots | Up to 20 kg | Up to 1.0 m | ± 0.02 mm | Assembly, Material Handling |

| Cartesian Robots | Up to 500 kg | Customizable | ± 0.1 mm | Material Handling, CNC Machining |

Understanding ROI: Calculating Cost vs. Efficiency in Automation

When considering the integration of manufacturing robots into production processes, understanding the return on investment (ROI) is crucial. Calculating the cost versus efficiency in automation requires a detailed analysis of both upfront and ongoing expenses. This includes not only the initial purchase price of the robots but also installation, maintenance, and any necessary training for staff. It is important to account for these factors to gain a realistic view of the financial commitment involved in automation.

On the efficiency side, evaluating the impact of robots on productivity is essential. Automation can significantly reduce production time, increase output quality, and minimize errors associated with manual labor. By comparing the pre-automation productivity levels against the post-automation performance, manufacturers can quantify improvements and better understand the value added through robotic implementation. This analysis helps identify if the investment will pay off within a reasonable timeframe, ultimately guiding manufacturers in choosing the right robots that align with their specific production needs.

Assessing Integration Capabilities with Existing Manufacturing Systems

When selecting the right manufacturing robots, one crucial factor to consider is their integration capabilities with existing systems. Manufacturers often rely on a variety of machines, software, and workflows, making compatibility a key concern. The ideal robot should seamlessly connect with existing machinery, ensuring that data flows smoothly between units and processes. Evaluate the communication protocols supported by potential robots and how they align with your current infrastructure. This step will help avoid the potential pitfalls of investing in automation that cannot effectively synchronize with established systems.

Furthermore, consider the ease of integration as a vital element of your decision-making process. Some robots come with comprehensive software solutions that facilitate quick deployment, while others may require extensive programming and configuration. Determine the level of support provided by the robot manufacturer, including documentation, training, and troubleshooting assistance. A robot that is user-friendly and offers robust integration tools will minimize downtime and enhance productivity, allowing your manufacturing operations to adapt and evolve effortlessly as technology advances.

Analyzing Industry Trends and Data to Predict Future Robot Needs

The analysis of industry trends indicates a significant evolution in the manufacturing landscape, driven by advancements in robotics and artificial intelligence. As companies increasingly adopt automation to enhance productivity, it's essential to predict future robot needs through thorough data analysis. Key sectors are placing emphasis on real-time data transmission and the integration of IoT devices, which are set to bolster the demand for industrial robotics. By closely monitoring these trends, manufacturers can better align their robot choices with production requirements and anticipated market shifts.

The emergence of new startups and innovative AI tools presents exciting opportunities for manufacturers looking to optimize their operations. The growing interest in edge AI technology is propelling the sector, facilitating quicker decision-making and improved efficiency on the shop floor. With industrial robot installations experiencing unprecedented growth, the challenge lies in selecting the right technology that not only meets current demands but is also adaptable for future challenges. Continuous market analysis and a forward-thinking approach will be critical in making informed decisions about the right manufacturing robots for evolving production needs.

Trends in Manufacturing Robot Adoption (2020-2025)

This chart illustrates the projected growth in manufacturing robot units sold from 2020 to 2025. As companies increasingly adopt automation solutions, the demand for manufacturing robots is expected to rise significantly, reflecting industry trends towards enhanced production efficiency and modernization.

Related Posts

-

Revolutionizing Manufacturing: How Industrial Robotics Are Shaping the Future of Automation

-

The Rapid Growth of Industrial Robotics Revolutionizing Manufacturing with 80 Percent Productivity Increase

-

Exploring the Future of Manufacturing: The Rise of Cartesian Robots in Automation

-

Exploring the Future of Manufacturing Robots in Smart Factories

-

Revolutionizing Manufacturing: How Pick and Place Robots Optimize Efficiency by 30% in Production Lines

-

Revolutionizing Automation: How Cartesian Robots Shape the Future of Precision Engineering