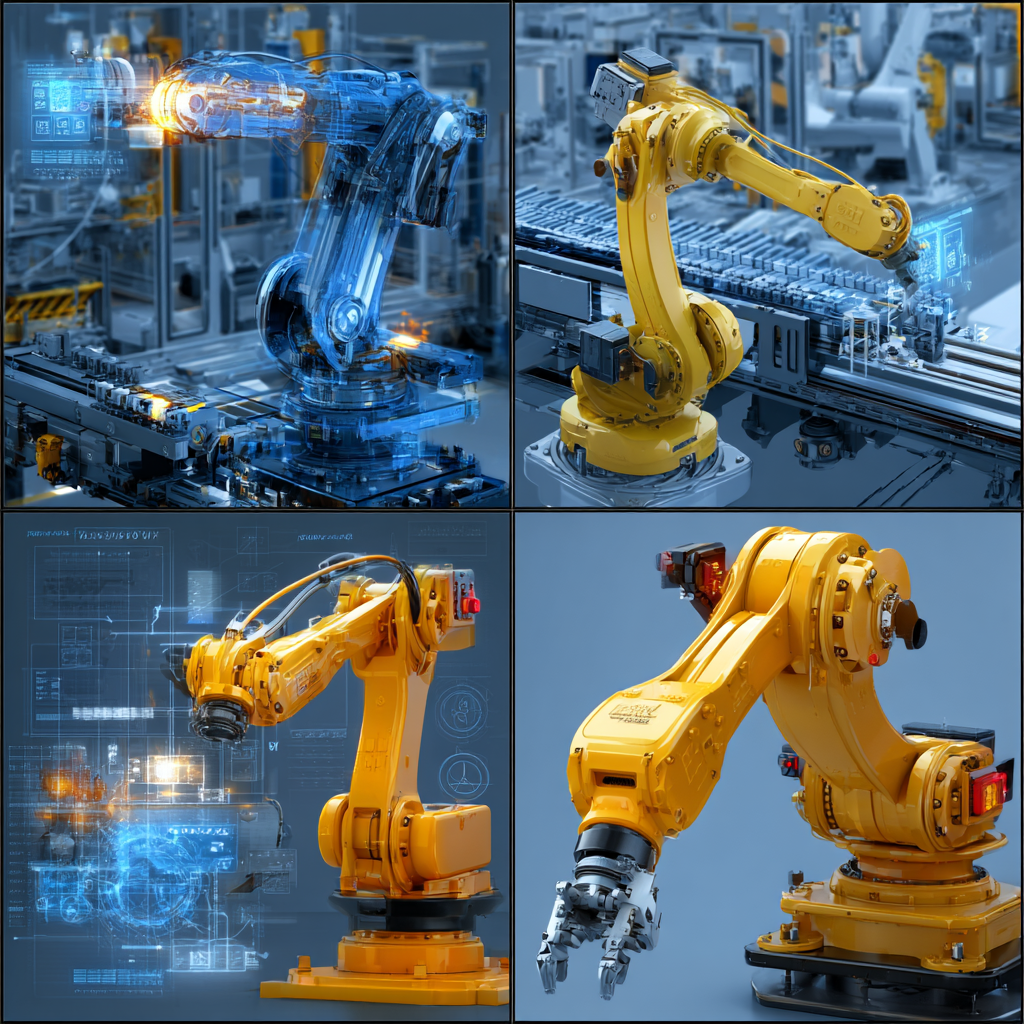

2025 How to Choose the Best Machine Tending Robot for Your Business Needs

In the rapidly evolving landscape of manufacturing, selecting the right machine tending robot is crucial for enhancing operational efficiency and maximizing production capabilities. According to a recent industry report by MarketsandMarkets, the global market for machine tending robots is expected to reach $7.5 billion by 2025, growing at a CAGR of 12.3% from 2020. This rapid growth underscores the importance of understanding the specific needs of your business when considering investment in automation technology.

As manufacturing processes become more advanced, industry experts emphasize the significance of tailoring solutions to fit individual requirements. Dr. John Smith, a prominent figure in robotics and automation, notes, "Choosing the right machine tending robot not only improves productivity but also optimizes workflow and reduces labor costs." His insights reflect the vital considerations that companies must evaluate, from payload capacities to integration capabilities with existing systems, ensuring that businesses invest wisely in automation.

As we explore the "2025 Top 5" machine tending robots, we will delve into the critical factors to consider, helping you make informed decisions that align with your business goals and drive future growth in this competitive environment. Whether you're a small manufacturer or a large enterprise, understanding these elements is key to optimizing your operations with the right machine tending robot.

Identifying Your Business Requirements for Machine Tending Automation

Identifying your business requirements for machine tending automation is crucial to selecting the right robot. Start by evaluating the specific tasks that need to be automated. Consider the types of machines involved, such as CNC machines, injection molding machines, or 3D printers, as different robots are optimized for different applications. Assess the operational environment, including the available space and any safety regulations that must be followed.

**Tips**: Engage your team in discussions to gather insights on workflow bottlenecks, as their input can significantly influence the choice of a machine tending robot. Additionally, analyzing the payload capacities and cycle times will ensure that the selected robot meets your production demands without causing delays.

Next, consider the scalability of your automation solution. Your business may grow or change over time, so it's important to choose a robot that can be easily upgraded or integrated with other systems. Understanding future needs will help you avoid investing in a solution that quickly becomes obsolete.

**Tips**: Create a list of must-have features versus nice-to-have features for your robot. This will clarify priorities and help in comparing different models and manufacturers effectively.

Evaluating Types of Machine Tending Robots and Their Applications

When evaluating types of machine tending robots for your business needs, it's essential to consider their specific applications and capabilities. According to a report by the International Federation of Robotics, the demand for collaborative robots, or cobots, is expected to grow by over 25% annually through 2025. These robots excel in environments where human-robot interaction is crucial, allowing for efficient handling of materials in processes like CNC machining and plastic injection molding. Their versatility makes them suitable for small and medium-sized enterprises looking to increase productivity without extensive investments in safety measures.

Additionally, industrial robots with higher payload capacities are gaining traction for more demanding applications. A study from the Boston Consulting Group highlighted that investing in heavy-duty robots can lead to a 30% reduction in labor costs and significantly improve production speeds. For businesses in sectors such as automotive and aerospace, these robots can handle intricate machine tending tasks while ensuring precision and reliability. By understanding the range of options available, companies can select machines that not only fit their current operational needs but also scale alongside future growth.

Key Features to Consider When Selecting a Machine Tending Robot

When selecting a machine tending robot for your business needs, it is crucial to consider several key features that can significantly impact efficiency and productivity. One of the most critical attributes is the robot's payload capacity. According to the International Federation of Robotics (IFR), demand for collaborative robots is set to grow, particularly in sectors like manufacturing and assembly, where payload capabilities should be aligned with operational requirements. Businesses must assess the weight and size of the parts being handled to choose a robot that can meet these demands effectively.

Another important factor is the robot's flexibility and ease of programming. As industries evolve towards more custom and diverse product lines, robots must adapt to different tasks without requiring extensive reprogramming. A 2021 report by MarketsandMarkets indicates that the global market for machine tending robots is projected to reach $6.83 billion by 2026, highlighting the need for robots that can seamlessly integrate into various workflows. Additionally, features like enhanced vision systems and AI capabilities can further streamline operations, allowing for greater automation and reducing potential errors in human oversight.

Understanding Budget Constraints and ROI for Robotics Investment

When choosing the best machine tending robot for your business needs, understanding the financial implications is critical. Small-to-mid-sized manufacturers (SMMs) often face significant hurdles when it comes to robotics adoption, primarily due to budget constraints and the complexities of workforce readiness. Reports indicate that innovation budgets are rising, reflecting a broader recognition among industry leaders that integrating robotics is essential for future supply chain success. In fact, a recent study highlighted that 51% of decision-makers in the brand and agency sector intend to increase their budgets for innovative technology this year, further emphasizing the importance of investing in automation to maintain competitiveness.

Moreover, determining the true cost of robotics goes beyond just initial investment. It's essential to account for both hidden costs and benefits associated with robotic deployment. A thorough analysis can uncover opportunities for cost savings and efficiencies that may be overlooked. For instance, in the realm of e-commerce, optimizing sponsored search through AI-powered systems has shown to significantly enhance revenue contributions, underscoring the potential of smart investments in technology. Businesses must navigate these budgetary considerations carefully to ensure that their robotics investments yield a strong return on investment (ROI), enabling them to scale operations effectively while overcoming existing workforce challenges.

Machine Tending Robots: Cost vs. ROI Analysis (2025)

This chart illustrates the estimated costs and projected return on investment (ROI) for different types of machine tending robots, highlighting the importance of understanding budget constraints when selecting robotic solutions for your business.

Assessing Vendor Reputation and Support for Long-term Success

When selecting a machine tending robot for your business, the reputation of the vendor plays a critical role in ensuring long-term success. According to a report by MarketsandMarkets, the global robotic automation market is expected to reach $41.7 billion by 2026, underscoring the competitive landscape that vendors operate within. It is essential to evaluate potential suppliers not only on their technological capabilities but also on their history in providing reliable support and service. A vendor with a solid reputation often indicates a commitment to quality and customer satisfaction.

Furthermore, engaging with a vendor that offers robust post-sales support can significantly mitigate operational risks. A study published by McKinsey highlights that companies that prioritize strong vendor relationships in automation projects can improve their ROI by as much as 30%. This statistic emphasizes the importance of evaluating the support structures, such as training programs and maintenance services, that vendors provide. Investing in a partner with a proven track record of support will not only enhance the performance of your robotic systems but also contribute to the scalability and adaptability of your automation strategies over time.

Related Posts

-

Why You Should Invest in a Pick and Place Robot for Your Assembly Line Efficiency

-

Revolutionizing Manufacturing: How Industrial Robotics Are Shaping the Future of Automation

-

Revolutionizing Automation: How Cartesian Robots Shape the Future of Precision Engineering

-

The Rapid Growth of Industrial Robotics Revolutionizing Manufacturing with 80 Percent Productivity Increase

-

Why Choose a Pick and Place Robot? Boost Efficiency with 70% Increased Productivity

-

Exploring the Future of Manufacturing Robots in Smart Factories