How to Choose the Right Pick and Place Robot for Your Automation Needs

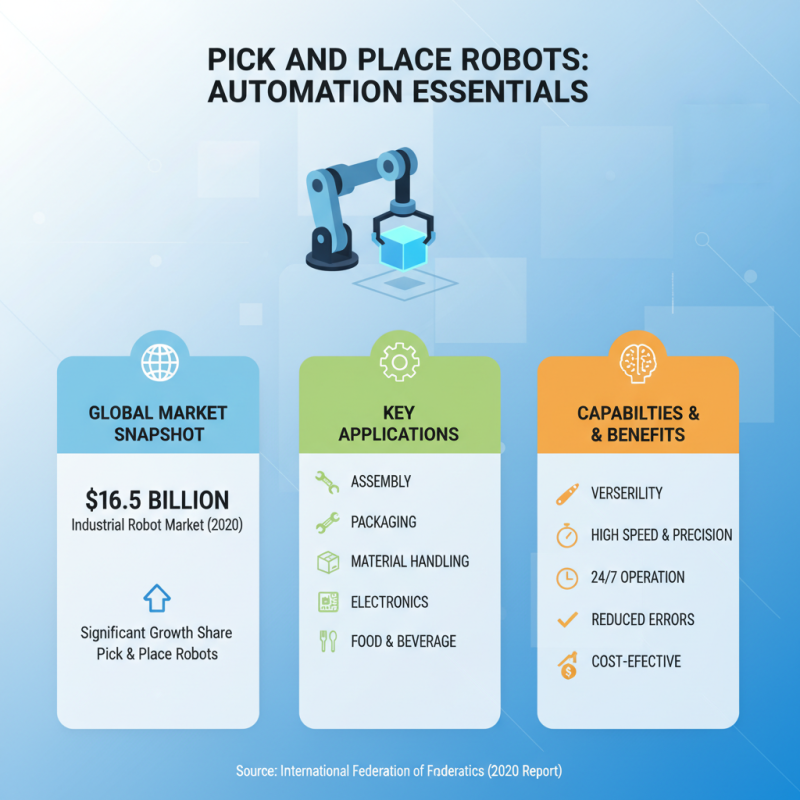

As industries increasingly pivot towards automation to enhance efficiency and productivity, the adoption of pick and place robots has surged dramatically. According to a report by the International Federation of Robotics, the global market for industrial robots, particularly pick and place robots, is expected to grow at a compound annual growth rate (CAGR) of 12% from 2021 to 2026. This growth underscores the necessity for businesses to comprehend their unique needs when selecting the appropriate pick and place robot, as the variety of available options can be overwhelming.

The versatility of pick and place robots allows them to be utilized across diverse applications, from manufacturing and packaging to assembly and logistics. A recent market analysis identified that approximately 30% of all automation investments in the manufacturing sector are directed towards pick and place solutions. However, choosing the right robot requires a thorough understanding of factors such as payload capacity, speed, precision, and integration compatibility. Addressing these considerations is paramount, as they can significantly impact operational efficiency and return on investment.

As companies strive to remain competitive in an ever-evolving marketplace, the importance of selecting the right pick and place robot tailored to specific automation needs cannot be overstated. By leveraging industry insights and data-driven approaches, businesses can make informed decisions that enhance their automation strategies and drive long-term success.

Understanding the Basics of Pick and Place Robots

Pick and place robots are essential in modern automation, designed to efficiently handle a variety of tasks, from assembling products to sorting and packaging. Understanding the basics of these robots involves recognizing their core components and functionalities. Typically, a pick and place robot consists of a robotic arm, gripper, and control system, which work together to identify, pick up, and accurately place items in designated locations. The versatility in design allows these robots to adapt to different weights, sizes, and shapes of products, making them suitable for various industries.

When choosing a pick and place robot, it’s crucial to consider your specific automation needs. One tip is to evaluate the speed and precision required for your tasks, as different robots have varying capabilities in these areas. Additionally, take into account the workspace and layout of your facility. A compact design might be more suitable if space is limited, while a more extensive setup can accommodate larger, more robust machines.

Another important aspect is the ease of programming and integration. Opt for robots that offer user-friendly interfaces and support robust software, allowing for easier adaptation to changing production requirements. As technology advances, consider future scalability; selecting a robot that can grow with your business will ensure a long-term investment in your automation strategy.

How to Choose the Right Pick and Place Robot for Your Automation Needs

| Dimension | Specification | Importance |

|---|---|---|

| Payload Capacity | Up to 10 kg | Critical for handling object weight |

| Reach | 0.5 m to 2 m | Determines operational space |

| Speed | Up to 150 picks/min | Affects production efficiency |

| Accuracy | ±0.5 mm | Essential for quality control |

| Integration | Compatible with various systems | Important for system compatibility |

| Types of End Effectors | Vacuum, Grippers, Customized | Influences object handling capabilities |

Identifying Your Automation Requirements and Goals

When selecting the right pick and place robot for your automation needs, it's essential to start by clearly identifying your automation requirements and goals. According to a report by the International Federation of Robotics, the global sales of industrial robots are projected to reach 4 million units by 2025, highlighting the growing demand for automation in various sectors. Companies must evaluate their specific applications, such as the weight and dimensions of items to be handled, the required speed of operation, and the precision needed for tasks. These considerations will significantly influence the type of robot best suited for the job.

Furthermore, understanding the operational environment is crucial. A study from the Association for Advancing Automation found that 60% of manufacturers are increasing their investments in automation due to the need for improved efficiency and safety in their production lines. Identifying whether your processes require flexibility for different product sizes or a dedicated solution for high-volume output will help in selecting a robot that meets both current and future demands. By aligning these automation goals with the capabilities of various pick and place robots, businesses can enhance productivity and maintain competitive advantage in an increasingly automated landscape.

Evaluating Different Types of Pick and Place Robots

When evaluating different types of pick and place robots for automation, it’s essential to consider their applications and capabilities. According to a report by the International Federation of Robotics, the global market for industrial robots reached $16.5 billion in 2020, with pick and place robots accounting for a significant portion of this growth. Their versatility makes them ideal for various tasks, including assembly, packaging, and material handling across numerous industries, from electronics to food and beverage.

Different designs of pick and place robots are available, primarily classified into SCARA, delta, and collaborative robots (cobots). SCARA robots, known for their speed and precision, are widely used in automated assembly lines. Delta robots excel in high-speed applications and can efficiently handle lightweight components, making them perfect for packaging and sorting tasks. Collaborative robots, on the other hand, work alongside human operators, enhancing flexibility in production environments. A study by MarketsandMarkets indicates that the collaborative robot market is expected to reach $12.3 billion by 2025, reflecting a growing demand for user-friendly automation solutions.

In addition to design and application, it's essential to consider payload capacity, speed, and the workspace configuration required for your specific tasks. Choosing the right type of pick and place robot involves balancing these factors against the desired level of automation and efficiency. A comprehensive understanding of your production challenges, along with the capabilities of different robot types, will ultimately lead to more informed purchasing decisions.

Key Features to Consider When Choosing a Robot

When selecting a pick and place robot for your automation needs, several key features require careful consideration. One of the most important factors is the robot’s payload capacity, which dictates how much weight the robot can handle. According to recent industry reports, over 60% of companies prioritize payload specifications as critical in their purchasing decisions. The payload must align with the products being handled to ensure efficient operations and minimize wear and tear on the robot.

Another essential feature to evaluate is the robot’s precision and repeatability. High-precision robots can significantly enhance production quality, especially in sectors like electronics and pharmaceuticals. Current studies show that robots with a precision rating of +/- 0.1 mm can improve output quality by 30%, reducing waste and increasing customer satisfaction. Additionally, consider the robot’s speed; faster robots can lead to higher throughput, which is vital for maintaining a competitive edge in the market.

Tips: Before committing to a pick and place robot, conduct a thorough analysis of your plant layout and workflow to determine the optimal configuration. Also, investing in robots with flexible programming options will allow you to adapt to future changes in production demands more easily. Finally, ensure the selected robot’s compatibility with existing systems for seamless integration and minimal downtime.

Budgeting and Cost Implications for Automation Solutions

When considering the integration of pick and place robots into your operations, budgeting and cost implications are critical factors that can significantly impact your automation strategy. According to a report by MarketsandMarkets, the global industrial robotics market is projected to reach $73.83 billion by 2026, with a compound annual growth rate (CAGR) of 10.5%. This growth indicates the increasing reliance on automation technologies, yet choosing the right solutions still demands a careful analysis of both upfront and long-term costs.

When budgeting for automation solutions, it’s essential to account for various cost components beyond the initial purchase price of the robot. These can include installation expenses, maintenance contracts, software licensing, and training for personnel. A study from the International Federation of Robotics highlights that while the initial investment in robotic solutions can be daunting, the potential for increased efficiency and reduced labor costs can yield a return on investment (ROI) within two to five years, depending on specific operational circumstances.

**Tips:**

1. Conduct a thorough cost-benefit analysis to uncover the total cost of ownership, including all hidden costs involved in deployment and operation.

2. Don't overlook the value of scalability; investing in modular robots can allow for expansion as your needs grow, ultimately optimizing your budget allocation.

3. Explore financing options, as many providers offer leasing or payment plans, making it easier to incorporate advanced robotics into your existing budget without sacrificing cash flow.

Comparative Costs of Different Types of Pick and Place Robots

Related Posts

-

Revolutionizing Automation: How Cartesian Robots Shape the Future of Precision Engineering

-

Exploring the Future of Manufacturing Robots in Smart Factories

-

Revolutionizing Manufacturing: How Pick and Place Robots Optimize Efficiency by 30% in Production Lines

-

The Rapid Growth of Industrial Robotics Revolutionizing Manufacturing with 80 Percent Productivity Increase

-

Revolutionizing Manufacturing: How Industrial Robotics Are Shaping the Future of Automation

-

Exploring the Future of Manufacturing: The Rise of Cartesian Robots in Automation