Top 10 Benefits of Automated Storage for Efficient Inventory Management

In today's fast-paced business environment, efficient inventory management has become paramount for companies striving to maintain competitive advantage. One of the most transformative solutions available is automated storage, a technology that streamlines the handling and organization of inventory, ultimately enhancing operational efficiency. This innovative approach not only minimizes human error but also maximizes storage capacity, allowing businesses to optimize their workflows and reduce retrieval times.

Automated storage systems integrate advanced technologies that facilitate real-time tracking, easy accessibility, and accurate inventory counts, which are crucial for successful inventory management. Businesses can leverage these systems to respond swiftly to market demands, improve order fulfillment rates, and significantly reduce operational costs. As organizations increasingly prioritize productivity and efficiency, understanding the multifaceted benefits of automated storage becomes essential. This article explores the top ten advantages that such systems provide, highlighting how they can transform inventory management practices and contribute to an overall increase in organizational performance.

Benefits of Automated Storage: An Overview of Efficiency and Cost Savings

Automated storage systems have become increasingly vital for businesses aiming to enhance inventory management efficiency and achieve significant cost savings. According to a report by the Warehousing Education and Research Council (WERC), companies that implement automated storage solutions can reduce their operational costs by up to 30%. This reduction is largely attributed to decreased labor costs and improved space utilization, as automation allows for a more streamlined approach to inventory handling.

Moreover, automated storage systems contribute to inventory accuracy, which is critical in managing supply chain operations effectively. A study by the Association for Automatic Identification and Mobility (AIM) indicates that organizations using automated inventory management experience error rates as low as 1% compared to traditional methods, where rates can be as high as 30%. This increased accuracy not only leads to better customer satisfaction through timely and correct order fulfillment but also minimizes losses associated with overstocking and stockouts, ultimately fostering a healthier bottom line.

Reducing Human Error: The Role of Automation in Inventory Accuracy

Automated storage systems have become increasingly vital for businesses looking to enhance their inventory accuracy while minimizing human error. Studies have shown that manual inventory processes are prone to inaccuracies, with error rates reported as high as 20% in some sectors. According to a report by the Inventory Management Institute, implementing automated systems can reduce these errors by up to 80%, significantly improving inventory turn rates and operational efficiency. The reliance on automation not only streamlines the inventory management process but also ensures that data is recorded with precision, making it easier for businesses to track stock levels in real-time.

Further emphasizing the benefits, a survey conducted by the Logistics Automation Research Group highlights that companies using automated storage solutions reported a 25% decrease in stock discrepancies and a 30% increase in overall productivity. This transformation occurs largely because automation eliminates the potential for human oversight in tasks such as item counting and data entry. With real-time updates and integrated software systems, organizations can maintain higher levels of inventory accuracy, resulting in better forecasting and demand planning. As a result, businesses can allocate their resources more effectively and respond more dynamically to market changes, ensuring they remain competitive in an increasingly automated landscape.

Top 10 Benefits of Automated Storage for Efficient Inventory Management - Reducing Human Error: The Role of Automation in Inventory Accuracy

| Benefit | Description | Impact on Inventory Accuracy (%) | Reduction in Human Error (%) |

|---|---|---|---|

| Increased Speed | Automated systems can retrieve and store inventory faster than manual processes. | 95 | 70 |

| Space Optimization | Automation maximizes storage capacity by organizing items efficiently. | 90 | 60 |

| Reduced Labor Costs | Less manual intervention means lower staffing requirements. | 85 | 50 |

| Enhanced Accuracy | Automation reduces miscounts and misplaced items, improving accuracy. | 98 | 80 |

| Real-Time Tracking | Automated systems allow for real-time inventory updates. | 99 | 75 |

| Improved Reporting | Automated systems generate accurate inventory reports quickly. | 90 | 55 |

| Better Stock Management | Automation facilitates better reorder levels and stock management. | 95 | 65 |

| Reduced Waste | Accurate tracking minimizes overstock and expiration issues. | 88 | 70 |

| Scalability | Automated systems can easily scale up with business growth. | 92 | 60 |

| Enhanced Security | Automation improves security through controlled access and monitoring. | 94 | 50 |

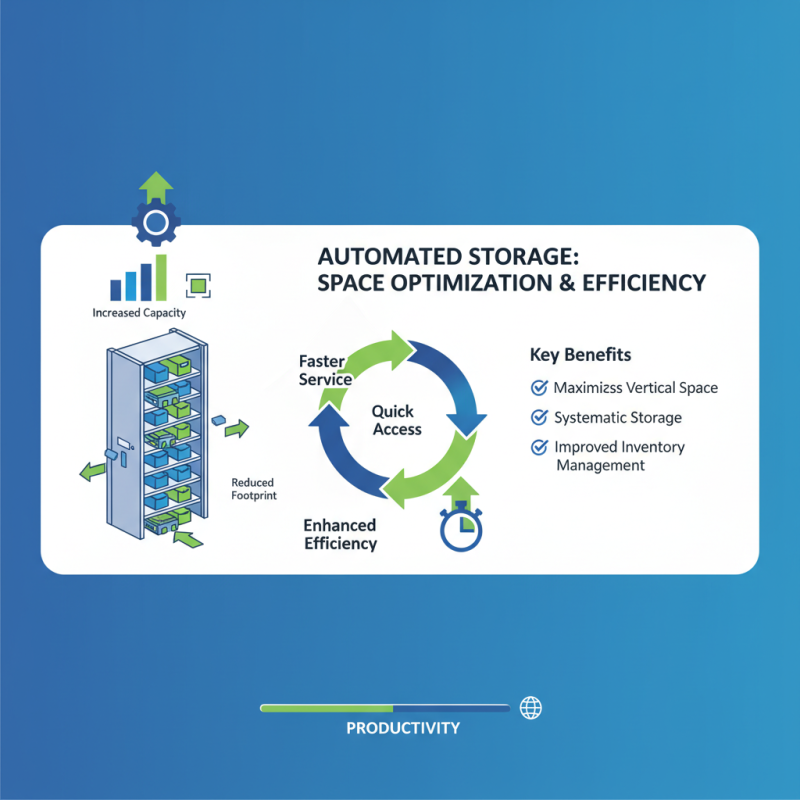

Space Optimization: How Automated Storage Increases Warehouse Capacity

Automated storage systems play a crucial role in space optimization within warehouses, enhancing overall efficiency in inventory management. By utilizing vertical space and minimizing the footprint of storage areas, these systems allow warehouses to significantly increase their capacity without the need for expanding physical locations. This maximization of space is particularly important as demand for faster service and quick access to products continues to rise. Automated storage solutions eliminate wasted spaces typically associated with traditional shelving systems, allowing for more items to be stored securely and organized systematically.

Moreover, automated storage enhances the ability to manage diverse inventory types while still optimizing space. Advanced technologies enable the efficient arrangement of products based on size, weight, and turnover rates. This strategic placement not only saves space but also streamlines the picking process, allowing quicker access to goods. As a result, warehouses can maintain a higher inventory turnover with less risk of overstocking or understocking items. The smart design and functionality of automated systems empower businesses to operate with greater agility, responding to market changes swiftly and effectively, all while utilizing their available space to its fullest potential.

Real-Time Inventory Tracking: Enhancing Supply Chain Visibility and Control

Real-time inventory tracking is a critical component of modern supply chain management, providing businesses with the agility and insight needed to enhance operational efficiency. By automating storage systems, organizations can gain immediate access to inventory levels, replenishment needs, and product movement.

This instant visibility allows teams to respond swiftly to fluctuations in demand, ensuring that stock levels are maintained efficiently without the risk of overstocking or stockouts. The ability to see inventory in real-time empowers businesses to make informed decisions, optimizing their inventory turnover rates and reducing waste.

Moreover, enhanced supply chain visibility fosters improved collaboration among stakeholders. When all members of the supply chain have access to real-time inventory data, they can coordinate more effectively, aligning production schedules, transportation logistics, and inventory management.

This transparency not only streamlines operations but also strengthens relationships among suppliers, distributors, and retailers, creating a more cohesive supply chain. Ultimately, implementing automated storage with robust inventory tracking transforms inventory management from a reactive to a proactive strategy, enabling organizations to achieve greater competitive advantage in their markets.

Cost Reduction through Automation: Analyzing ROI in Inventory Management

Automated storage systems have revolutionized inventory management by significantly reducing operational costs. According to a study by the Warehousing Education and Research Council (WERC), companies that implement automation in their inventory processes can achieve a cost reduction of up to 30%. This reduction often stems from decreased labor costs and minimized errors in inventory handling. Furthermore, the return on investment (ROI) for automated inventory solutions can be realized within one to two years, making it a financially sound decision for businesses looking to improve efficiency.

Tip: When considering automation, assess your current inventory management costs. Track labor hours and error rates to better understand potential cost savings. Leveraging data analytics can also help identify specific areas where automation would yield the most significant ROI.

Automation not only enhances cost efficiency but also increases accuracy, leading to improved customer satisfaction. A report by McKinsey & Company highlights that businesses with automated inventory systems experience a 25% increase in inventory accuracy. This boost helps in reducing excess inventory and ensures timely fulfillment of orders, further enhancing overall operational efficiency.

Tip: Implement a pilot program for automation in a small segment of your inventory. This allows you to measure the immediate impact on accuracy and cost-efficiency, tailoring your approach before a full-scale rollout.

Top 10 Benefits of Automated Storage for Efficient Inventory Management

Related Posts

-

Top 7 Manufacturing Robots Revolutionizing the Industry in 2023

-

The Rapid Growth of Industrial Robotics Revolutionizing Manufacturing with 80 Percent Productivity Increase

-

How to Optimize Fanuc Robot Programming for Maximum Efficiency and Productivity

-

2025 How to Choose the Best Machine Tending Robot for Your Business Needs

-

How to Efficiently Use XYZ Gantry for Your Next Project Guide

-

Revolutionizing Manufacturing: How Industrial Robotics Are Shaping the Future of Automation