What is Automated Storage and How Does it Benefit Your Business

Automated storage has revolutionized the way businesses manage their inventory and assets. As industries continue to evolve towards enhanced efficiency and reduced operational costs, the implementation of automated storage systems has become a critical strategy for maintaining competitiveness. According to Dr. Emily Stanford, a leading expert in automated storage solutions, "The integration of automated storage systems not only optimizes space but also streamlines processes, resulting in significant cost savings and improved accuracy."

In the rapidly changing landscape of modern business, traditional storage methods are often insufficient to meet the demands for agility and speed. Automated storage offers a sophisticated approach, utilizing advanced technologies such as robotics and artificial intelligence to facilitate faster retrieval and management of goods. This transition is not just about modernization; it's about future-proofing operations against the challenges of a dynamic marketplace.

Through automated storage, businesses can achieve a multitude of benefits, including enhanced inventory management, reduced labor costs, and improved order fulfillment times. As more companies leverage these innovative systems, understanding their potential and implementation becomes essential for those aiming to thrive in today's competitive environment. The journey into automated storage is not just a trend; it is an essential evolution in operational strategy.

What is Automated Storage?

Automated storage refers to the use of advanced technology and systems to manage the storage and retrieval of goods without the need for manual intervention. In warehouses and distribution centers, automated storage solutions can take various forms, including automated shelving, robotic systems, and high-density storage systems. These technologies streamline the process of organizing, storing, and accessing products, facilitating efficient inventory management and reducing the likelihood of human error.

The primary benefit of automated storage systems is their ability to maximize space utilization while improving operational efficiency. By employing vertical storage solutions and robotic retrieval systems, businesses can significantly increase their storage capacity in a smaller footprint. This not only leads to cost savings but also minimizes the time employees spend searching for items, resulting in faster order fulfillment. Furthermore, automated storage systems contribute to improved safety in the workplace by reducing the risks associated with manual handling and ensuring that products are stored securely.

Benefits of Automated Storage for Businesses

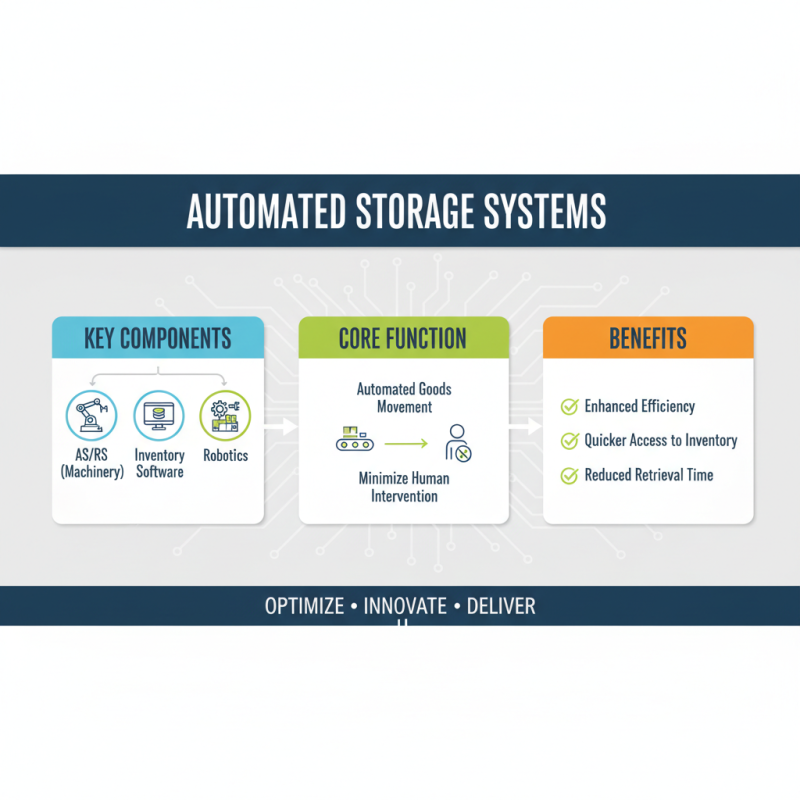

Key Components of Automated Storage Systems

Automated storage systems are designed to optimize the storage and retrieval of goods through advanced technology, significantly enhancing efficiency in various business environments. The key components of these systems typically include automated storage and retrieval systems (AS/RS), inventory management software, and robotics. AS/RS consist of machinery that automatically handles the movement of items within a warehouse, minimizing the need for human intervention. This technology ensures quicker access to inventory, reducing the time spent in locating and retrieving products.

Inventory management software plays a crucial role by integrating with automated storage systems to provide real-time tracking and data analysis. This software allows businesses to maintain accurate stock levels, forecast demand, and streamline order processing. Coupled with robotics, which can automate sorting and packing processes, these components create a seamless flow of operations, significantly reducing labor costs and errors associated with manual handling. Overall, the combination of these elements fosters a more organized and efficient storage environment, contributing to improved operational performance and better service delivery to customers.

Benefits of Automated Storage for Businesses

Automated storage systems are revolutionizing the way businesses manage their inventory and space. One of the primary benefits of automated storage is a significant efficiency increase in storage and retrieval processes. By utilizing advanced technology, companies can minimize the time employees spend locating and handling products, which not only boosts productivity but also enables faster order fulfillment. Automation reduces human error, ensuring that items are stored and retrieved accurately, which is crucial in maintaining inventory integrity.

Moreover, automated storage solutions can lead to substantial cost savings over time. By maximizing space utilization, businesses can reduce their overall storage footprint, potentially lowering rent and operational costs associated with larger warehouse facilities. The integration of automation also allows for better management of resources, enabling companies to allocate their workforce more effectively.

As a result, staff can focus on value-added tasks rather than repetitive manual labor, fostering innovation and strategic growth within the organization. With these advantages, automated storage represents a compelling investment for businesses looking to enhance their operational efficiency and competitive edge.

Implementation Challenges and Considerations

Implementing automated storage systems presents a unique set of challenges and considerations that businesses must navigate to fully realize their potential benefits. One significant hurdle is the integration of new technology into existing infrastructure. Companies must assess the compatibility of automated systems with current processes, machinery, and warehouse layouts. This often requires a substantial upfront investment in both time and resources to ensure a seamless transition, which can be a deterrent for some organizations.

Another challenge lies in the need for proper staff training and adaptation. Automation can significantly change workflows, and employees will need to be equipped with the skills to operate and maintain the new systems effectively. Resistance to change among staff can also pose a barrier, as it may require a cultural shift within the organization. To mitigate these issues, businesses should focus on clear communication of the benefits of automation and invest in comprehensive training programs that help employees transition smoothly into their new roles.

Lastly, ongoing maintenance and updates are crucial considerations post-implementation. Automated systems require regular monitoring and occasional upgrades to remain efficient and effective. Organizations must have a strategy in place for maintenance, ensuring they can quickly address any technical issues that arise and minimize downtime. By carefully considering these challenges, businesses can better position themselves to leverage automated storage solutions to enhance efficiency and productivity.

What is Automated Storage and How Does it Benefit Your Business - Implementation Challenges and Considerations

| Dimension | Description |

|---|---|

| Storage Efficiency | Automated storage systems maximize space utilization through dynamic allocation and compact storage methods. |

| Speed of Retrieval | Automation enhances the speed of retrieving items, reducing wait times and improving overall operational efficiency. |

| Inventory Accuracy | Automated systems improve inventory tracking, leading to higher accuracy in stock levels and reduced discrepancies. |

| Labor Cost Reduction | By minimizing the need for manual labor, automated storage solutions can lead to significant reductions in labor costs. |

| Implementation Challenges | Challenges may include high initial investment, integration with existing systems, and change management among staff. |

| Scalability | Automated storage solutions can easily scale up or down according to business needs, making them flexible for varying market demands. |

| Safety and Security | Automated systems provide enhanced security for valuable inventory and minimize workplace injuries through mechanized handling. |

Future Trends in Automated Storage Solutions

As businesses strive to enhance efficiency and meet the demands of an increasingly fast-paced market, automated storage solutions are gaining significant traction. One future trend is the integration of artificial intelligence (AI) with automated storage systems. This advancement allows for smarter inventory management, where AI can predict stock needs based on historical data, adjust storage dynamically, and reduce the risk of overstocking or stockouts. Companies adopting this technology will likely see improved accuracy in order fulfillment and resource allocation.

Another promising trend is the rise of modular and scalable automated storage systems. This flexibility enables businesses to adapt their storage solutions to evolving needs without extensive overhauls. Modular systems can be easily expanded or reconfigured as inventory requirements change, making it an attractive option for growing businesses. Additionally, these systems can incorporate IoT technology for real-time monitoring, providing insights into operational efficiency and enabling proactive maintenance.

Tips for businesses looking to implement automated storage solutions include starting with a thorough assessment of your current storage needs and workflows. Understanding the specific pain points can help you choose the right technology. Moreover, consider the long-term scalability of the solution to ensure it supports future growth without significant additional investment. Regular training for staff on new systems will also enhance productivity and ease the transition into automated processes.

Related Posts

-

Top 10 Benefits of Automated Storage for Efficient Inventory Management

-

Why Is Automated Storage Essential for Modern Businesses?

-

What is a Manufacturing Robot and How It Revolutionizes Modern Industries

-

The Rapid Growth of Industrial Robotics Revolutionizing Manufacturing with 80 Percent Productivity Increase

-

Revolutionizing Logistics with Automated Material Handling Solutions in Modern Warehousing

-

Why Choose a Pick and Place Robot? Boost Efficiency with 70% Increased Productivity